-

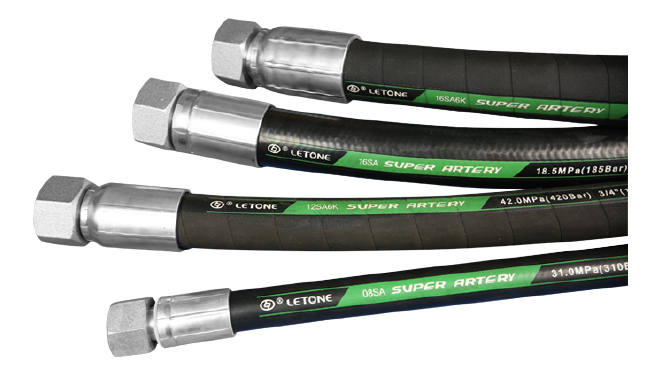

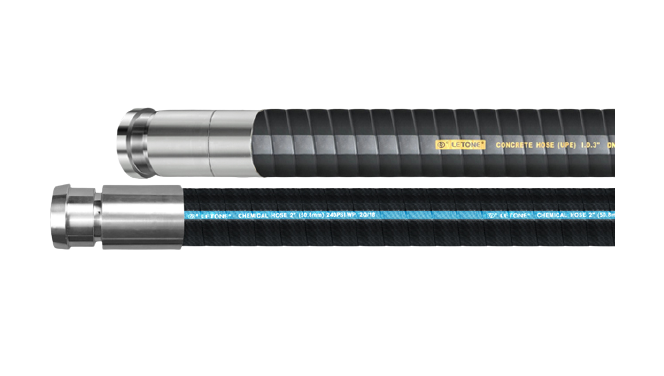

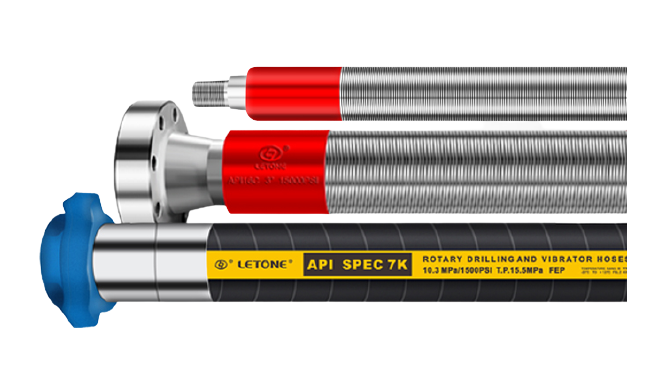

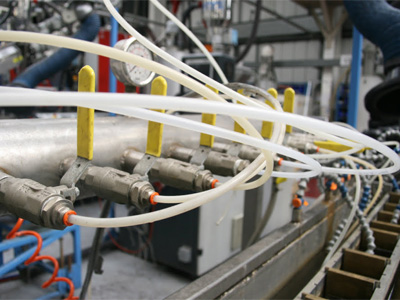

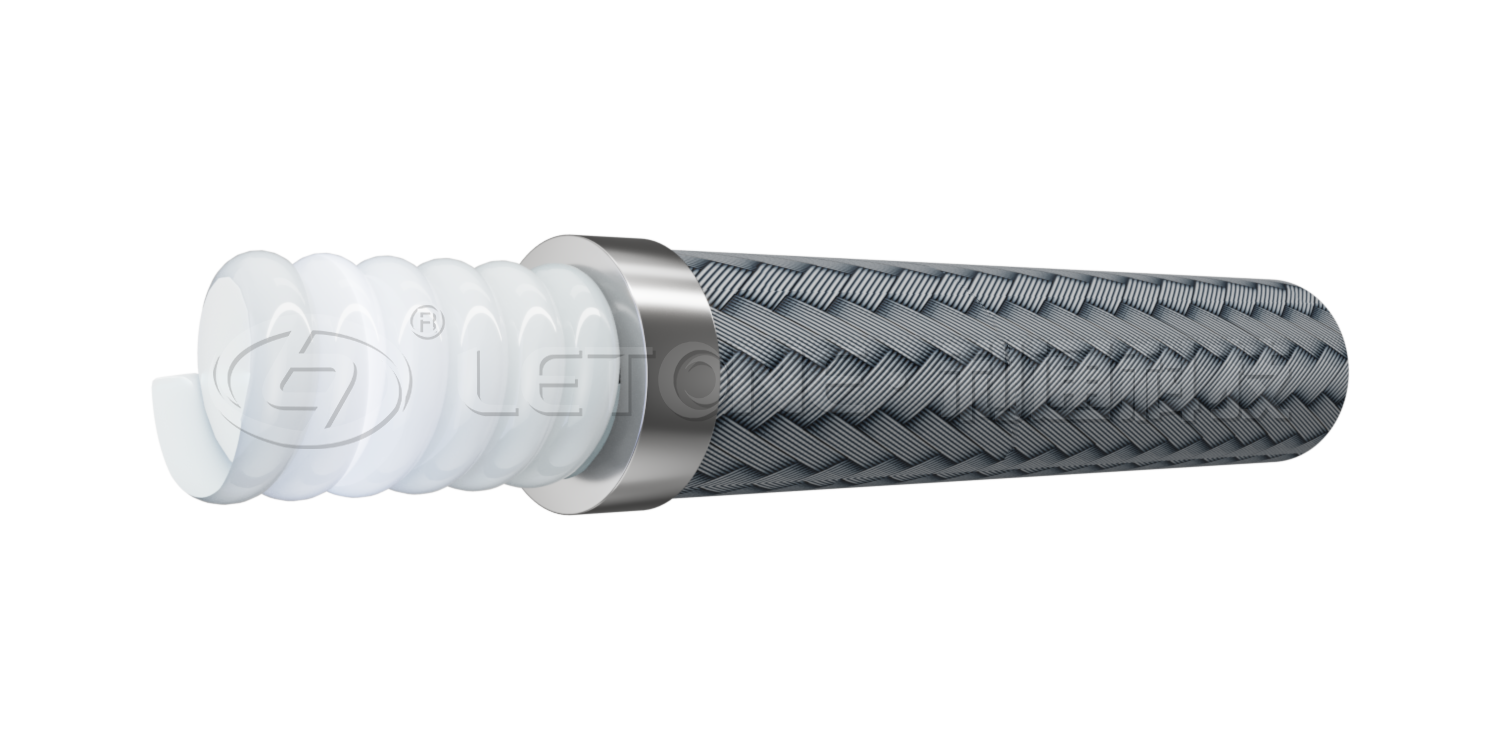

Recycled nylon material PFA chemical hose HPP OEM services Warm Isostatic Pressing API 17K jumper hose Data centre water cooling Long life excavator hose Mine Total Growth Life Hose Special topic of municipal hose network dredging Construction Hydraulic Raising Topics acid fracturing Heat Exchangers and Gaskets Ultra-high pressure cleaning hose topic Oil drilling hose Chemical Delivery Hose Super Hercules Hose Material conveying hose