-

PA11/PA12 - Automotive applications

low-pressure fuel line:Recycled materials can be utilized for manufacturing

low-pressure fuel delivery pipes and ventilation ducts. Typically, they are applied in a

multi-layer co-extrusion structure, where the recycled material serves as the core layer,

while virgin materials are used for the inner and outer layers to ensure cleanliness and

long-term performance.

-

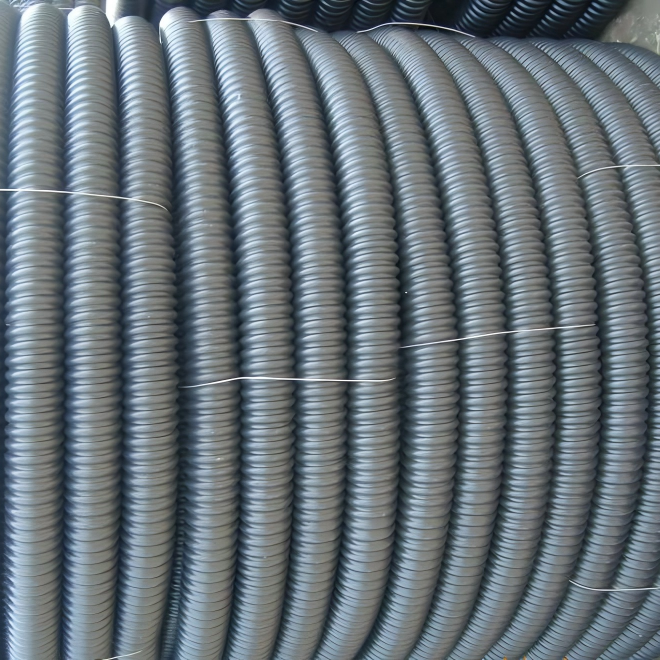

PA11/PA12 - Automotive applications

Fuel pipe sheath / corrugated tube:It does not come into direct contact

with the fuel. Instead, it serves as an outer protective tube, taking advantage of its

flexibility and oil resistance.

-

PA11/PA12 - Automotive applications

Brake fluid pipe sleeve:Also as the outer layer protection, the

requirements for temperature resistance and brake fluid resistance are lower than those for

the inner layer pipe.

Various tracheal and wiring sheaths:In environments such as the engine

compartment, the protective lines and pipelines are shielded from wear, high temperatures

and chemical erosion.

-

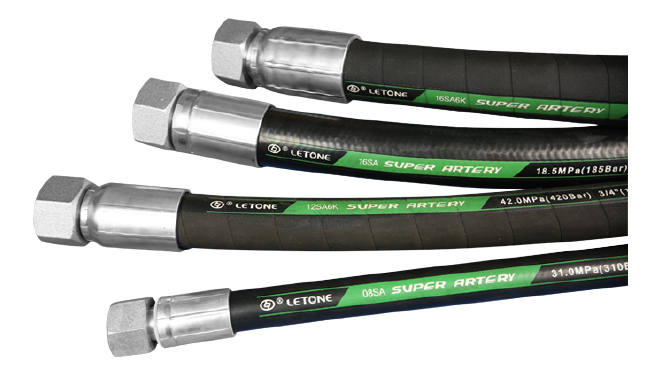

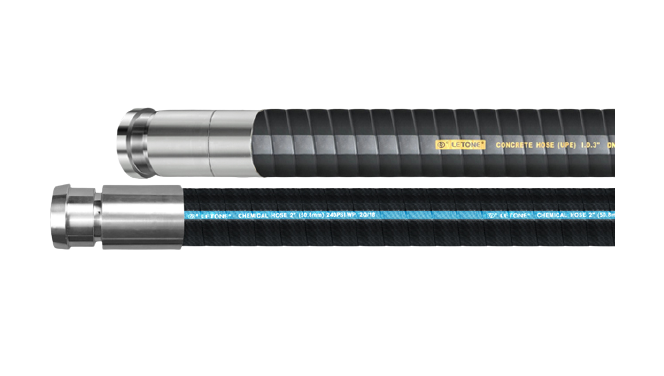

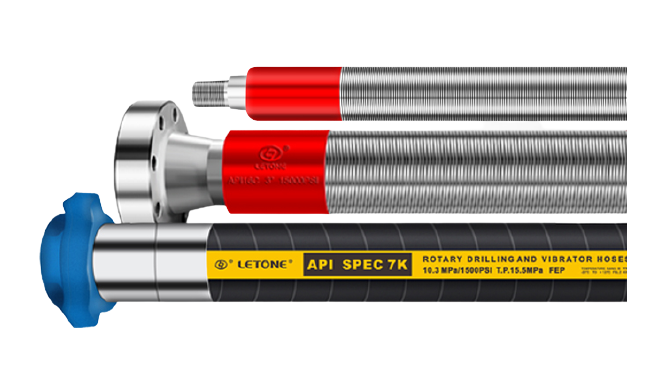

PA11/PA12 - Industrial Field

Compressed air pipe:For compressed air systems with low working pressure,

recycled PA11 pipes are an economical and practical choice.

-

PA11/PA12 - Industrial Field

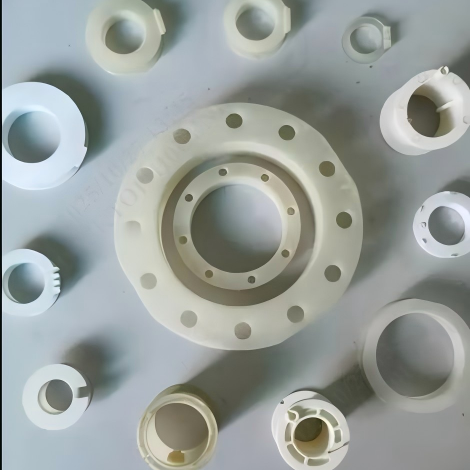

Wear-resistant liner, guide sleeve:In equipment such as mines and

agricultural machinery, the wear-resistant components are used for non-core stressed areas.

-

PA11/PA12 - Industrial Field

Flexible connector:A pipe connection that requires certain compensation for

bending and vibration.

-

PA11/PA12 - Sports Leisure

Ski boot shells, components of sports shoes:Take advantage of its excellent

low-temperature impact resistance and flexibility.

-

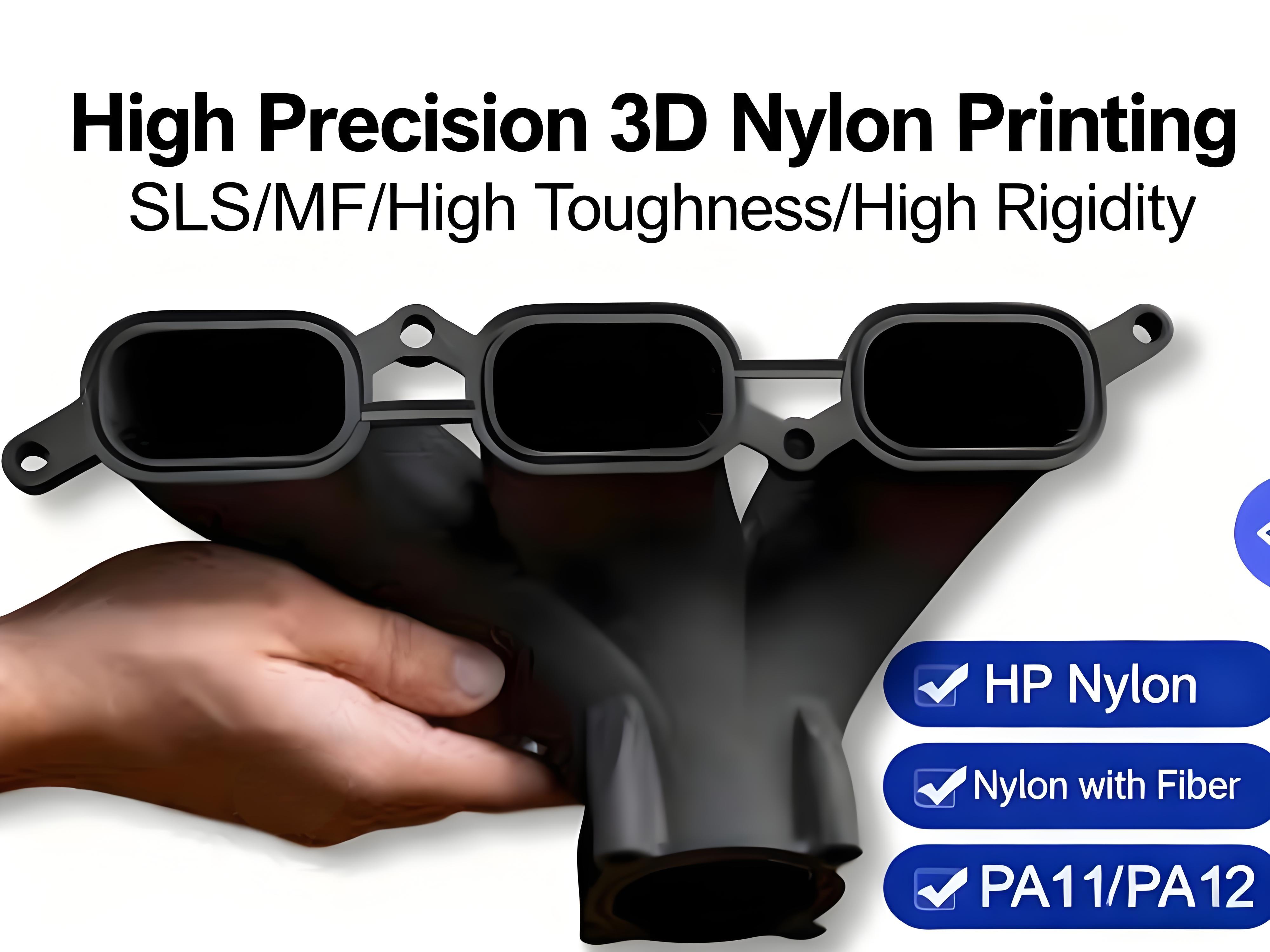

PA11/PA12 - 3D Printing Field

3D printing display models and teaching aids:Products with low requirements

for appearance and strength.

-

PA6 - Automotive Industry Sector

Components inside the engine compartment:For non-core structural components such as intake

manifolds, engine covers, and air ducts, the requirements for heat resistance are relatively

low.

Cooling system components:Such as the pump impeller, the end cover of the water tank (make

sure it has good hydrolytic resistance).

-

PA6 - Automotive Industry Sector

Electrical connector:Connector and sheath for automotive wiring harness.

Interior and exterior components:Doors handles, decorative strips, clasps, etc.

-

PA6 - Electronic and Electrical Field

Low-voltage electrical appliance enclosure:Such as the casings of switches, sockets, circuit

breakers, and small distribution boxes.

-

PA6 - Electronic and Electrical Field

Coil frame:Used for transformers, relays, etc.

-

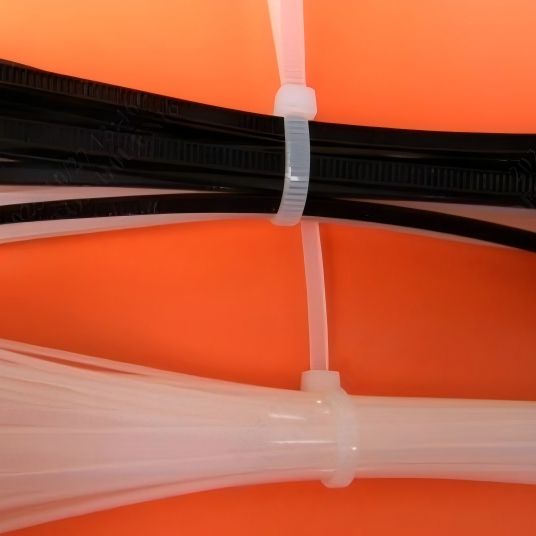

PA6 - Electronic and Electrical Field

Cable ties and sheaths:This is a very common application with relatively low requirements

for mechanical properties.

-

PA6 - Industrial and Consumer Products Sector

Office equipment:Chair legs, chair backs, gears inside the printer, structural components

(requiring wear resistance and low noise).

-

PA6 - Industrial and Consumer Products Sector

Household appliances:Electric tool casings, components of vacuum cleaners, handles and gears

of kitchen appliances.

-

PA6 - Industrial and Consumer Products Sector

Fishing gear:Some of the structural components of the fishing reel.

-

PA6 - Industrial and Consumer Products Sector

Sports equipment:Skateboard wheels, bicycle rims, bike locks, etc.

-

PA66 - Automotive Industry Sector

Radiator water tank:The excellent high-temperature resistant properties of PA66 make it

widely used in this field, and recycled materials can also be applied here.

-

PA66 - Automotive Industry Sector

Engine fan, fan cover:There are high requirements for heat resistance and strength.

-

PA66 - Automotive Industry Sector

Brake system components:Such as the brake fluid reservoir cap and other non-core safety

components.

-

PA66 - Automotive Industry Sector

Automobile connector:Especially, connectors that can withstand higher temperatures are

required in the engine compartment.

-

PA66 - Electronic and Electrical Field

High-temperature electrical components:Such as the components that need to come into contact

with high temperatures in items like electric irons, hair dryers and hot water boilers.

-

PA66 - Electronic and Electrical Field

Terminal block:It requires excellent flame retardancy and heat resistance.

-

PA66 - Electronic and Electrical Field

Electric tool casing:Require high rigidity and heat resistance.

-

PA66 - Industrial Field

Drone propellers, landing gear:It requires high rigidity and a certain degree of impact

resistance.

-

PA66 - Industrial Field

Mechanical structural components:Such as gears, bearings, rollers, guide rails, etc.,

require high wear resistance and high rigidity.