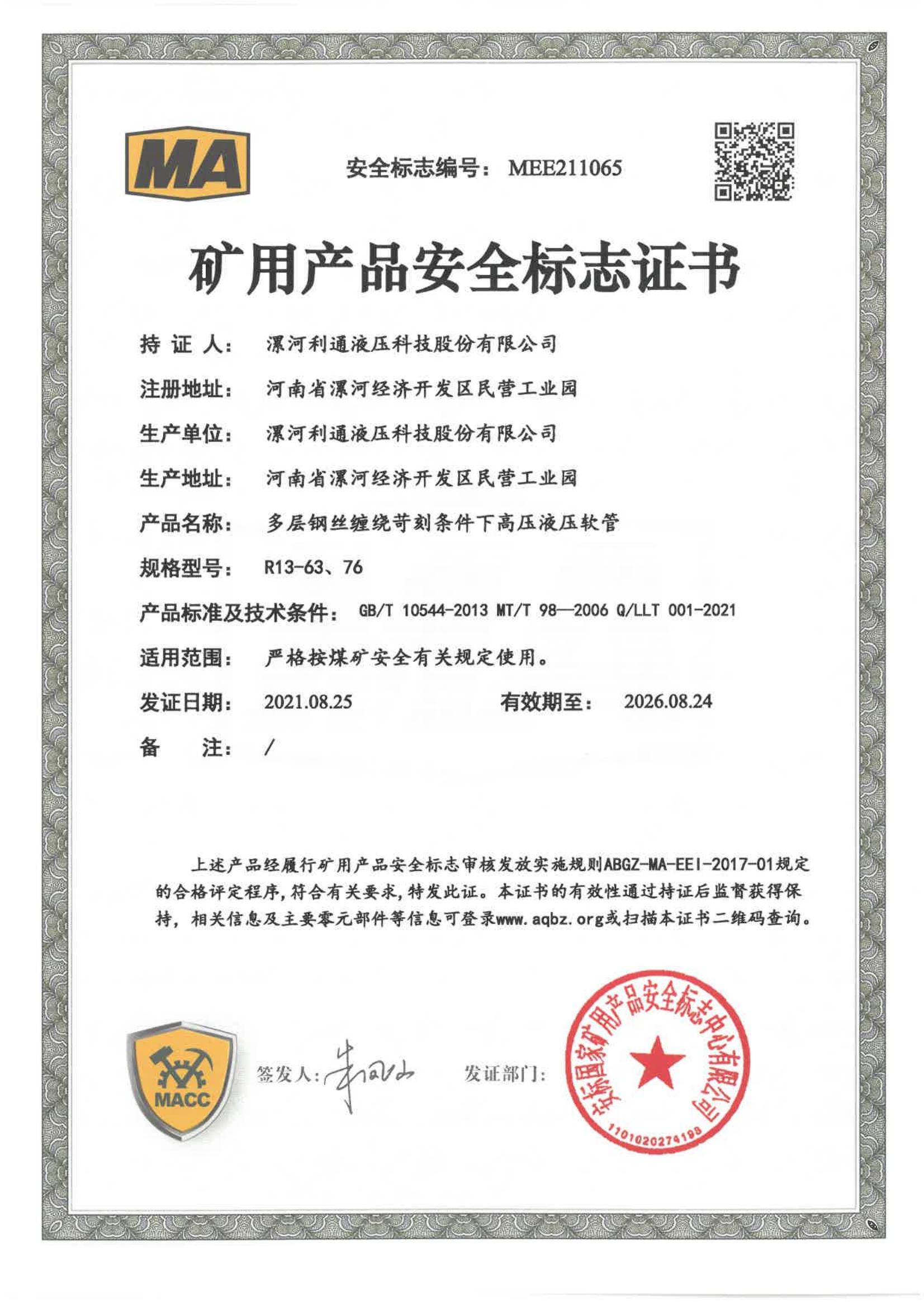

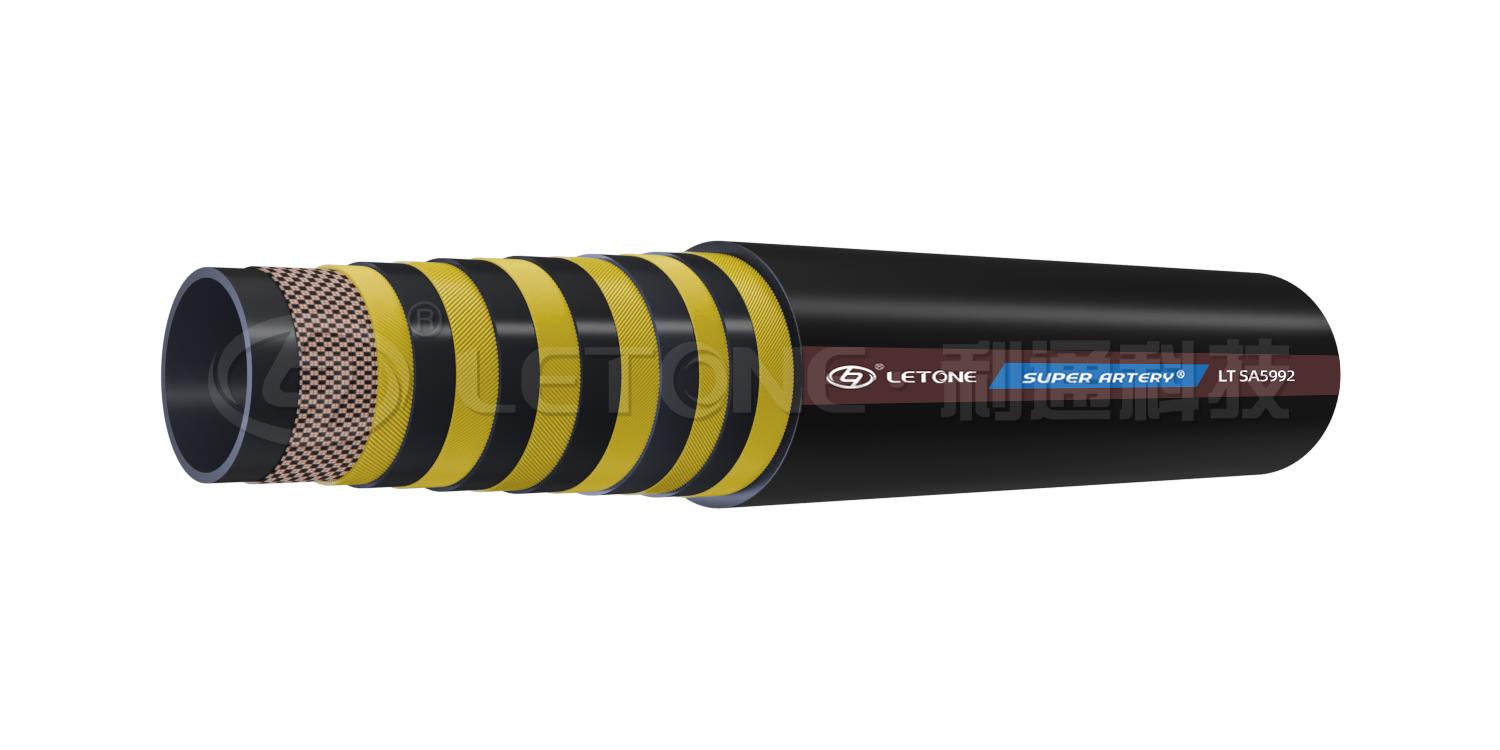

Harsh Environment Total Long Life Mining Hose

01

low bend

Bending radius is 34% lower than ISO18752 Class C standard

02

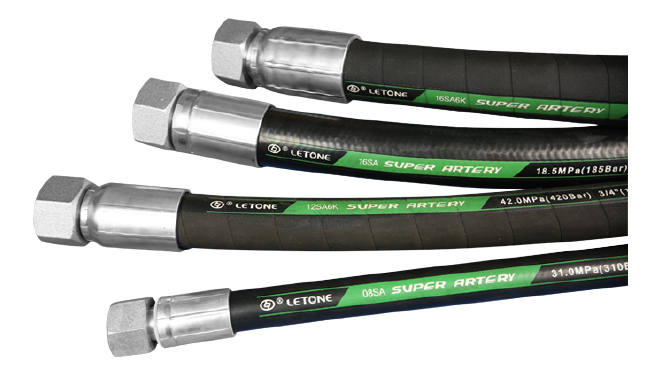

high pressure

The pressure is 25% higher than the SAE/DIN standard.

03

long life

The number of hose pulses is more than 1 million times.

04

Zero leakage

With the use of Letone Technology's self-developed hose joints and hydrogenated nitrile seals, the service life can exceed 5 years (two years warranty).

05

good service

Pipeline system integration solutions, strive to provide five "province" services of "time, labor, trouble, money, and worry".

-

Harsh environment 1: The on-site installation environment of fully mechanized mining equipment in coal mines is poor. Coal mine fully mechanized mining equipment represented by hydraulic supports is mainly used for underground coal mining operations. Due to the narrow space and complex environment during underground coal mining operations, it is extremely difficult to install and debug coal mine fully mechanized mining equipment.

Harsh environment 1: The on-site installation environment of fully mechanized mining equipment in coal mines is poor. Coal mine fully mechanized mining equipment represented by hydraulic supports is mainly used for underground coal mining operations. Due to the narrow space and complex environment during underground coal mining operations, it is extremely difficult to install and debug coal mine fully mechanized mining equipment. -

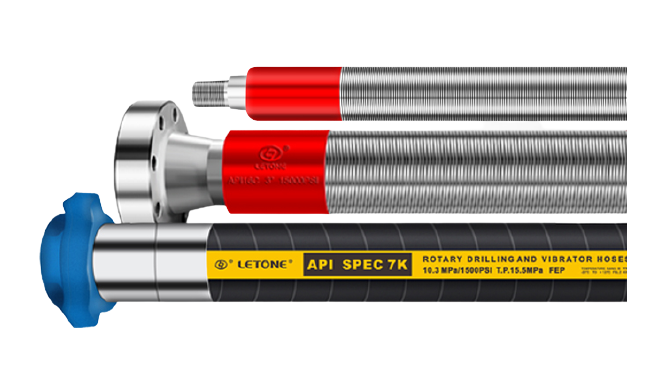

Harsh environment 2: The fully mechanized coal mining equipment is located in a harsh environment and bears a large load, thus forming a strong impact on the hydraulic system, which makes the hydraulic system prone to failure, thus affecting the safe production of coal mines.

Harsh environment 2: The fully mechanized coal mining equipment is located in a harsh environment and bears a large load, thus forming a strong impact on the hydraulic system, which makes the hydraulic system prone to failure, thus affecting the safe production of coal mines. -

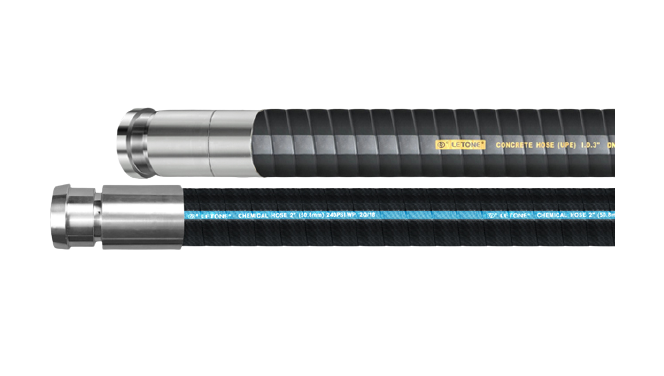

Harsh environment 3: The complex mining environment of coal mines and changes in external factors can easily lead to wear and tear on the hydraulic pipelines of fully mechanized mining equipment such as hydraulic supports, which in turn causes the rupture of the outer rubber of the hose, the rust and fracture of the steel wires of the pipe body, and the blasting of the hose body. Hydraulic system components operate abnormally and are prone to failure. The replacement frequency is high and the replacement cost is high.

Harsh environment 3: The complex mining environment of coal mines and changes in external factors can easily lead to wear and tear on the hydraulic pipelines of fully mechanized mining equipment such as hydraulic supports, which in turn causes the rupture of the outer rubber of the hose, the rust and fracture of the steel wires of the pipe body, and the blasting of the hose body. Hydraulic system components operate abnormally and are prone to failure. The replacement frequency is high and the replacement cost is high. -

Harsh environment 4: The hose assembly made of carbon steel as the hydraulic system components of the fully mechanized mining equipment is exposed to chemical waste liquid and humid environment for a long time, and the joints are easily corroded. The running, running, dripping and leaking of production equipment and pipelines caused by corrosion will seriously affect the production cycle and equipment life of production equipment, and increase production costs.

Harsh environment 4: The hose assembly made of carbon steel as the hydraulic system components of the fully mechanized mining equipment is exposed to chemical waste liquid and humid environment for a long time, and the joints are easily corroded. The running, running, dripping and leaking of production equipment and pipelines caused by corrosion will seriously affect the production cycle and equipment life of production equipment, and increase production costs.