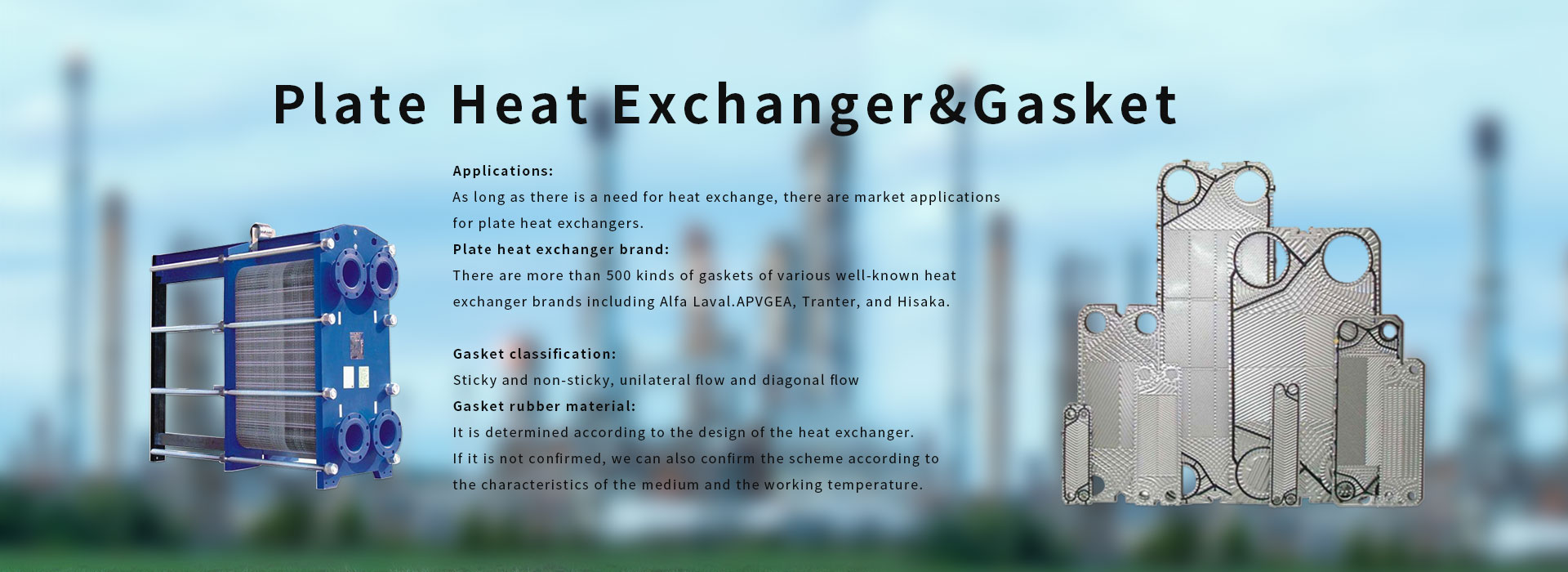

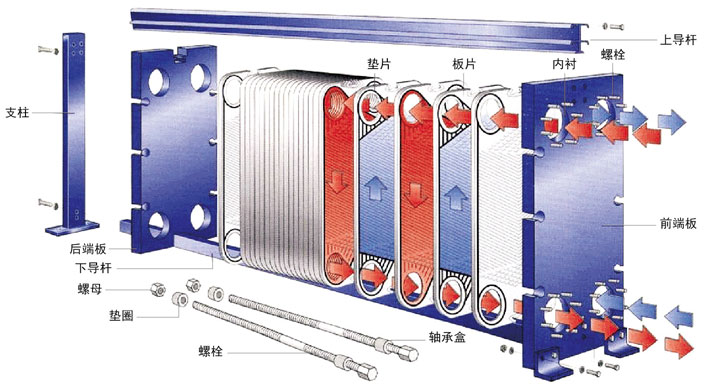

Manufacturing process of plate heat exchanger and gasket

The plate heat exchanger has the advantages of high heat exchange efficiency, small footprint, simple manufacture and simple maintenance, etc. It is suitable for district heating, domestic hot water, ice storage, swimming pool constant temperature in the field of HVAC; Cooling, process medium heating/cooling systems, etc., as well as electric power, steel, metallurgy, food, papermaking, shipbuilding, medicine, textiles, automobiles and other fields, as long as there is a need for heat exchange, there are market applications for plate heat exchangers. As part of plate heat exchanger gasket manufacturing, our team follows a precise and rigorous process at every stage;

-

1. Raw material supplyAll our components and elastomers are produced by ourselves to ensure the highest quality products.

1. Raw material supplyAll our components and elastomers are produced by ourselves to ensure the highest quality products. -

2. Tool manufacturing Manufacture your own molds in-house at its manufacturing site, with flexibility and responsiveness.

2. Tool manufacturing Manufacture your own molds in-house at its manufacturing site, with flexibility and responsiveness. -

3. Gasket manufacturing (molding) After the first extrusion step, the rubber is vulcanized in a press (17 in total, accommodating models from the smallest to the largest).

3. Gasket manufacturing (molding) After the first extrusion step, the rubber is vulcanized in a press (17 in total, accommodating models from the smallest to the largest). -

4. Quality control All seals are manually removed and visually inspected, then analyzed in the laboratory to check compliance with standards.

4. Quality control All seals are manually removed and visually inspected, then analyzed in the laboratory to check compliance with standards.