Focusing on ADIPEC 2025 | Letone Technology's scenario-based solutions adapt to a new path for inte

As a leading event for the Middle East's oil and gas industry, the Abu Dhabi Petroleum Exhibition and Convention Centre (ADIPEC) has become a platform for showcasing products, technologies, and services in the oil and gas sector to the world. It is the largest and most influential professional exhibition in the Middle East for this industry. On November 3rd, ADIPEC 2025 grandly opened at the Abu Dhabi International Exhibition Centre, bringing together global energy giants, technology pioneers, and industry leaders. With "Energy, Intelligence, and Impact" as its core theme, the event focused on exploring the deep integration of artificial intelligence and oil and gas development, seeking new directions for industrial upgrading in the context of global energy transition.

As a leading player in China's oil and gas equipment hose and fluid technology service sector, Letone Technology accurately understands the core needs of the Middle East market for "stable capacity growth + green efficiency improvement." At booth 16138, through multimedia displays, product brochures, and real-world application case studies, they created an immersive exhibition space showcasing "scenario adaptation + solution implementation." Targeting the three core scenarios of well completion, high-pressure extraction, and cementing operations in Middle Eastern oilfields, their one-stop integrated solutions—well completion fracturing solutions, high-pressure fire-resistant flexible choke control solutions, and cementing solutions—perfectly match the complex geology and extreme working conditions of the region. These solutions attracted representatives from global oilfield service companies and visitors, becoming one of the highlights of the exhibition.

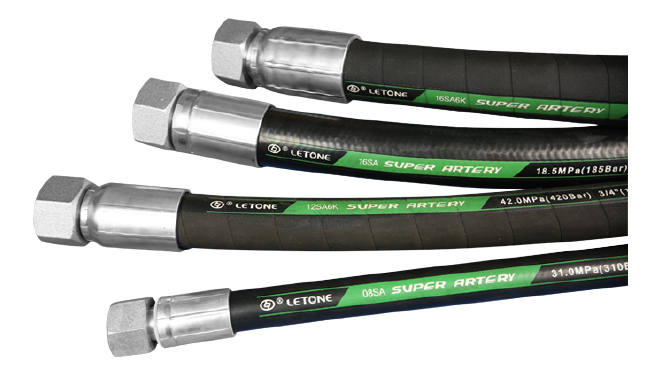

LT301F Ultra-Abrasion Resistant Acid Fracturing Hose

Middle Eastern oilfields often face high-intensity, high-frequency well completion and fracturing operations, and the LT301F ultra-wear-resistant acid fracturing hose is a core piece of equipment designed for this scenario. Whether it's the chemical media delivery in acid fracturing or the high-pressure operating environments of proppant fracturing and hydraulic fracturing, this hose uses hammer-driven unions or flanges as connectors, further enhancing the safety and pressure transmission efficiency of the hose manifold, reducing replacement frequency, and overcoming the shortcomings of traditional hard-tube fracturing operations, such as high single-well fracturing costs and low operational efficiency. Its field application results are outstanding (70% cost savings and doubled installation efficiency compared to steel pipes). This series of hoses has been widely used in shale oilfield fracturing operations in countries and regions such as the United States, Xinjiang, Shanxi, and Jilin, contributing to the efficient development of global energy.

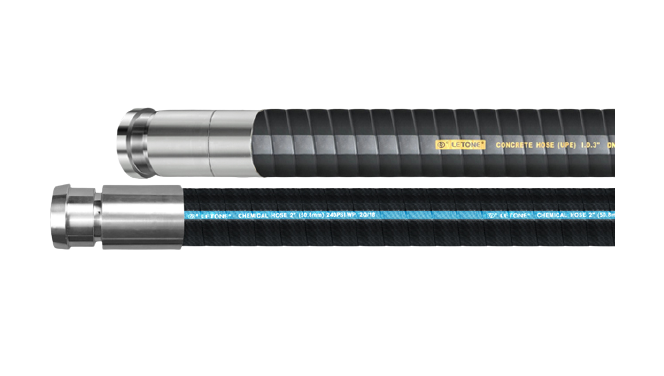

LT302 Flexible Throttling and Well Killing Pipeline

Middle Eastern oil and gas extraction often presents challenges in transporting high-pressure, high-risk media (such as hydrogen sulfide). The LT302 flexible throttling and kill fluid pipeline strictly adheres to international standards, constructing a comprehensive safety protection system. In scenarios such as emergency throttling and kill fluid transportation in high-pressure oil and gas wells, its high-strength pressure-bearing skeleton and fire-resistant outer layer design, along with flame-retardant and high-temperature resistant stainless steel armor as the outer protective layer, further enhance its core performance characteristics such as fire resistance, high pressure resistance, and wear resistance. Testing has shown that it can withstand a 705℃ open flame test for over 30 minutes, exceeding API standards in fire resistance. It fully meets the requirements for transporting oil and gas mixtures containing hydrogen sulfide and other hazardous gases, as well as various water-based, oil-based, and foam kill fluids under high pressure.

LT301 High-Pressure Cement Hoist

For cementing operations in the Middle Eastern desert regions characterized by large temperature differences and abundant dust, the LT301C high-pressure cement hose offers customized solutions. The inner layer material can be flexibly selected based on the geological conditions and mud characteristics of different oilfields. Its excellent heat resistance, oil resistance, and hydrogen sulfide resistance make it widely used in oilfield extraction projects. Meanwhile, the outer rubber layer of this hose is made of wear-resistant and weather-resistant synthetic rubber, possessing flame-retardant and ozone-resistant properties, significantly extending the hose's service life and maintenance period, continuously creating tangible value for customers.

Currently, the Middle East oil and gas industry is undergoing a critical transformation: on the one hand, countries in the region are continuously increasing upstream investment to consolidate their core position in global energy supply, leading to a surge in demand for oil and gas field development equipment that is adaptable to complex operating conditions and has low energy consumption; on the other hand, the application of artificial intelligence in exploration and operation is accelerating, carbon capture technology and low-carbon equipment are becoming industry standards, and "intelligent + green" is becoming a new development trend. This transformation not only provides a broad market space for oil and gas equipment companies, but also places higher demands on the scenario adaptability and low-carbon attributes of technical solutions.

As one of the earliest Chinese companies to establish a presence in the Middle East market, Letone Technology has always been guided by "scenario-based needs," continuously iterating its technologies and solutions around the characteristics of regional oil and gas development. This has led to a strategic upgrade from single-product supply to full-chain support encompassing "scenario-solution-service." While promoting the internationalization of Chinese independent brands, Letone Technology also leverages its intelligent innovation capabilities to contribute to regional energy transformation. Its participation in ADIPEC 2025 is not only an opportunity for Letone Technology to showcase its technology and strength but also an important platform for learning from international best practices and accurately grasping industry trends. Through in-depth exchanges with international peers and customers, Letone Technology has further clarified its technological innovation direction, accumulating valuable experience for future technology optimization and product portfolio expansion.

The ADIPEC 2025 exhibition is still in full swing. Letone Technology cordially invites global customers to visit booth 16138 to experience firsthand the implementation capabilities of its scenario-based solutions, explore new opportunities in the Middle East oil and gas market, and jointly usher in a new chapter of intelligent and low-carbon development.

-

Letone Hydraulics sincerely invites you to participate in the "Germany Hannover Messe" and "Bauma

-

From April 8th to 14th, Letone Hydraulics invites you to participate in the Bauma Exhibition of Muni

-

The Bauma exhibition in Munich is waiting for you at booth C5.114 / D from April 8th to 14th!

-

The first announcement of the environmental impact assessment of the Luohe Letone Hydraulic Technolo

-

We sincerely invite you to participate in the "2019 Fifth China (Changsha) International Constructi

-

Letone Hydraulic "Public Hose Smart Factory Project with an Annual Output of 50 Million Meters" Pu

-

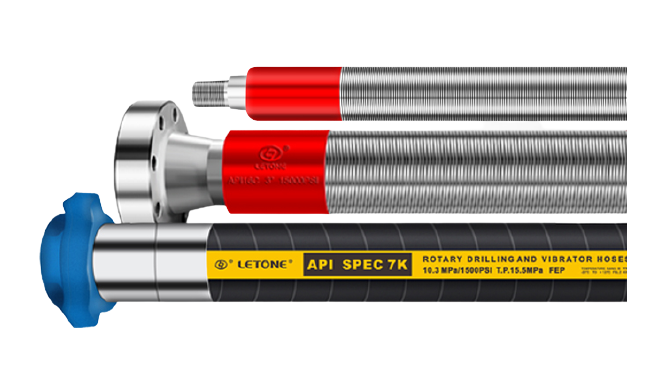

API 7K and API 16C series products successfully obtained ABS certification issued by American Bureau

-

Focusing on ADIPEC 2025 | Letone Technology's scenario-based solutions adapt to a new path for inte