Focusing on OTC Brasil 2025 | Litong Technology leverages its self-developed oil and gas pipeline so

As a benchmark event for the South American oil and gas industry, the OTC Brasil exhibition has grown in scale and influence since its inception in 2011, and has now developed into an important industry exhibition radiating throughout Brazil and even the entire South America. On October 28, OTC Brasil 2025 grandly opened in Rio de Janeiro, Brazil, bringing together global oil and gas companies, technology experts, and industry professionals to jointly envision the industrial development blueprint in the context of global energy transition, focusing on core topics such as "green and efficient extraction" and "deep-sea energy development."

Letone Technology, a leading manufacturer of hoses and fluid technology services for China's oil and gas industry, focused on the dual needs of "cost reduction and efficiency improvement + low-carbon transformation" in the Brazilian and South American markets. At booth E43 of the exhibition, they created an immersive "technology + scenario" showcase. Their independently developed core products, such as acid fracturing hoses, flexible choke and kill lines, and high-pressure cement hoses, along with one-stop solutions for unconventional oil and gas production enhancement and cementing manifolds, precisely matched the complex operating conditions of regional oil and gas exploration. This attracted representatives from globally renowned companies and visitors to stop and inquire, resulting in a lively atmosphere for on-site discussions.

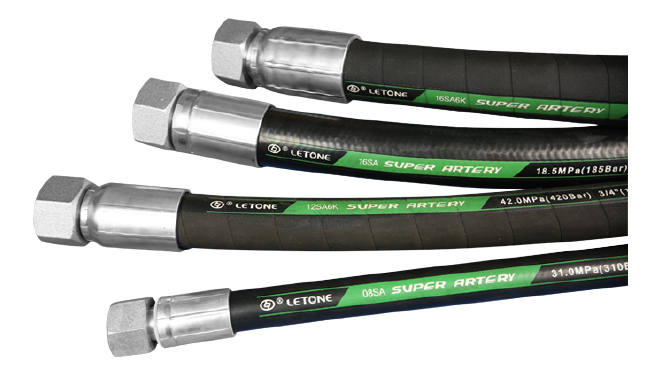

Ultra-abrasion resistant acid fracturing hose

The LT301F ultra-wear-resistant acid fracturing hose, as a culmination of domestic oil pipeline technology, significantly improves the safety and pressure transmission efficiency of hose manifolds when used with hammer unions or flanges as connectors, greatly reducing replacement frequency. It overcomes the shortcomings of traditional hard-pipe fracturing operations, such as high single-well fracturing costs and low operational efficiency. Its field application results are outstanding (70% cost savings and 2 times higher installation efficiency compared to steel pipes), providing an innovative model for the large-scale development of unconventional oil and gas resources worldwide.

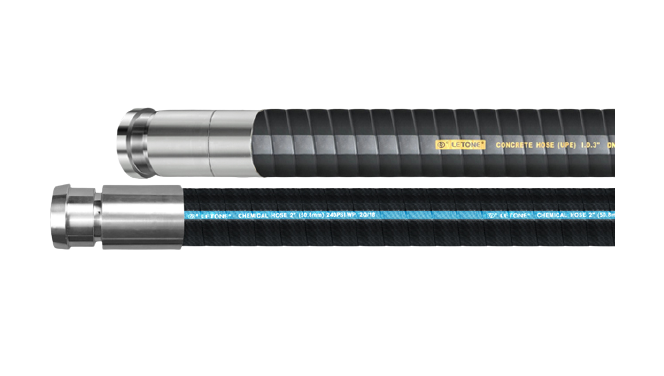

High-pressure cement hose

To meet diverse construction requirements, the LT301C high-pressure cement hose offers customized options for its inner layer material. Its excellent heat resistance, oil resistance, and H2S resistance make it widely used in oilfield extraction projects. Meanwhile, the hose's outer layer, made of wear-resistant and weather-resistant synthetic rubber, possesses flame-retardant and ozone-resistant properties, significantly extending the hose's service life and maintenance period, continuously creating tangible value for customers.

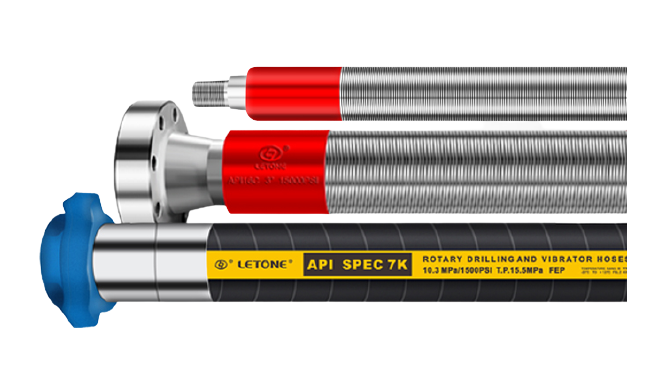

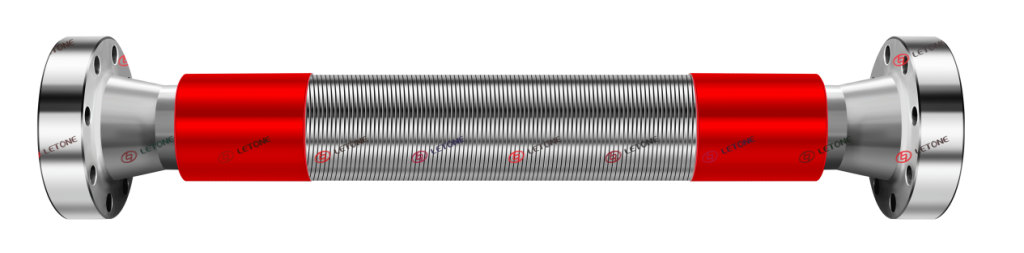

Flexible throttling and well-killing pipelines

The LT302 flexible choke and kill hose uses multi-layered wound high-strength ultra-flexible steel wire as the pressure-bearing skeleton material, further optimizing the hose's low bending and lightweight characteristics. Simultaneously, the outer rubber layer of the hose is made of high-temperature resistant and fire-resistant synthetic rubber, with a flame-retardant and high-temperature resistant stainless steel armor as the outer protective layer, further improving its fire resistance (withstanding a 705℃ open flame test for over 30 minutes, exceeding API standards), high pressure resistance, and wear resistance. This fully meets the requirements for transporting oil-gas mixtures containing hydrogen sulfide (H2S) and other hazardous gases, as well as various water-based, oil-based, and foam kill fluids under high pressure.

Brazil is becoming a key growth engine for the global oil and gas industry, and is projected to become one of the world's top five oil producers by 2030. Currently, it is undergoing a crucial transformation from "scale expansion" to "green and efficient" development. On the one hand, the government is mandating the construction of carbon capture and storage (CCUS) facilities in new oil fields to promote carbon reduction in the extraction process. On the other hand, digital and intelligent technologies are rapidly penetrating the market, and the coordinated development of offshore wind power and oil and gas is becoming a new trend. This transformation has not only created new demand for "low-carbon equipment" and "smart pipelines," but also provided Chinese companies with opportunities to deeply participate in regional energy transition.

As one of the earliest Chinese core component manufacturers of oil and gas equipment to establish a presence in the South American market, Letone Technology has always been guided by "local needs." Focusing on the fields of offshore oil and gas, unconventional oil and gas equipment, and oil and gas field drilling, Letone Technology prioritizes local demands for pipelines in terms of "high reliability, low operating costs, green transformation, and safe production." Building upon its solid product capabilities, the company strengthens its original and leading technological breakthroughs. With its self-developed high-end oil and gas pipeline products and systematic solutions, Letone Technology has become a key partner for global oil and gas service providers and large-scale integrated oilfield service equipment manufacturers. While expanding its global market footprint, Letone Technology is also leading a new wave of Chinese independent brands "going global," creating long-term value for global customers through high-level technological self-reliance.

Currently, OTC Brasil 2025 is still in full swing. Letone Technology cordially invites global customers to visit booth E43 to explore new opportunities in the South American oil and gas market, jointly unlock the infinite possibilities of energy development, and inject "Chinese power" into the regional energy transition.

-

Letone Hydraulics sincerely invites you to participate in the "Germany Hannover Messe" and "Bauma

-

From April 8th to 14th, Letone Hydraulics invites you to participate in the Bauma Exhibition of Muni

-

The Bauma exhibition in Munich is waiting for you at booth C5.114 / D from April 8th to 14th!

-

The first announcement of the environmental impact assessment of the Luohe Letone Hydraulic Technolo

-

We sincerely invite you to participate in the "2019 Fifth China (Changsha) International Constructi

-

Letone Hydraulic "Public Hose Smart Factory Project with an Annual Output of 50 Million Meters" Pu

-

API 7K and API 16C series products successfully obtained ABS certification issued by American Bureau

-

Focusing on ADIPEC 2025 | Letone Technology's scenario-based solutions adapt to a new path for inte