The petroleum and chemical industry delivered a high-quality development report card during the 14th

During the 14th Five-Year Plan period, under the strong leadership of the CPC Central Committee with Comrade Xi Jinping at its core, my country's petroleum and chemical industry adhered to the guidance of Xi Jinping Thought on Socialism with Chinese Characteristics for a New Era. Facing a complex international environment, it actively responded to major risks and challenges such as the COVID-19 pandemic, firmly grasped the main theme of high-quality development, adhered to the general principle of seeking progress while maintaining stability, overcame difficulties and made positive progress, promoted the deepening of supply-side structural reform, strengthened innovation-driven development, steadily expanded its scale, comprehensively improved the quality of development, and continuously consolidated its status as a major global oil and chemical power.

With its scale and efficiency steadily increasing, the industry's strength has reached a new level.

Both the scale and quality of production have improved simultaneously. By the end of 2024, the number of large-scale enterprises in my country's petroleum and chemical industry exceeded 32,000, with total operating revenue of 16.28 trillion yuan, an increase of 46.9% compared to 2020; total profits reached 789.71 billion yuan, an increase of 53.2%; total import and export volume reached 948.81 billion US dollars, an increase of 53.0%; and fixed assets reached 18.8 trillion yuan, an increase of 35.8%. Production scale has steadily expanded. The average annual growth rate of major chemical product output has remained at around 4.6%. The output of bulk chemical products such as ethylene, methanol, caustic soda, soda ash, calcium carbide, fertilizers, sulfuric acid, synthetic resins, pesticides, and tires has remained the world's largest, further solidifying China's position as a global chemical powerhouse. Energy security capabilities have been continuously strengthened. In 2024, China's crude oil production reached 210 million tons, a 9.2% increase, exceeding 200 million tons for the third consecutive year; natural gas production reached 246.37 billion cubic meters, a 30.5% increase, exceeding 10 billion cubic meters for the eighth consecutive year. The total length of long-distance oil and gas pipelines nationwide reached 195,000 kilometers, and the primary pipeline transportation capacity for natural gas climbed to 394 billion cubic meters, highlighting its role as a "ballast stone" for energy security. Enterprise competitiveness significantly improved. In 2024, 11 petroleum and chemical companies ranked among the world's top 50 chemical companies, marking the first time the number on the list exceeded double digits. The number of specialized and innovative manufacturing enterprises in the petroleum and chemical sector reached 165, and the number of specialized and innovative "little giant" enterprises reached 1,523, demonstrating significantly enhanced innovation vitality and development resilience.

Structural optimization has been deepened, and significant progress has been made in the transformation towards high-end products.

The "reducing oil consumption and increasing chemical production" strategy in the refining and chemical industry has yielded tangible results. The number of refineries with a capacity of over 10 million tons has increased from 33 to 36, and their share of the national total refining capacity has risen from 47.8% to 57.5%, further increasing industry concentration. The chemical product structure is accelerating its transformation towards "refinement and high-end" products. The refinement rate of chemicals has increased from 42% to 54%, and the output value of new chemical materials has exceeded one trillion yuan. Breakthroughs have been achieved in the industrialization of new chemical materials such as special engineering plastics, ultra-high purity electronic-grade hydrofluoric acid, and polyolefin elastomers. Polyurethane and its raw materials, as well as organofluorine and silicon materials, have achieved self-sufficiency. The self-sufficiency rate of thermoplastic elastomers and functional membrane materials has exceeded 80%. The market share of new fertilizers such as high-efficiency slow-release fertilizers and water-soluble fertilizers, as well as high-efficiency, low-toxicity, and low-residue pesticides and biological pesticides, continues to expand. The industry is gradually building a more diversified, efficient, and competitive industrial structure and product system.

Innovation capabilities have steadily increased, and the level of intelligence has continued to improve.

Significant achievements have been made in tackling key core technologies. Key technologies for high-temperature resistant silica-based aerogel composites, efficient and green manufacturing technologies for ultra-pure electronic chemicals used in chips, and key technologies for the preparation of high-performance polyamide materials have achieved industrial application, breaking through a number of "bottleneck" technologies. Theories and key technologies for drilling and completion of ultra-deep and complex oil and gas reservoirs, geological tracking rotary steerable drilling technology, and key technologies for the enrichment mechanism and evaluation of marine shale gas have moved from theory to practice, supporting the completion and commissioning of a number of major energy engineering projects. New progress has been made in bio-based and resource recycling technologies. Breakthroughs have been achieved in green synthesis technologies for vitamin D3 series products, low-odor automotive polypropylene platform technology, key technologies for the continuous flow microreactor system for AK sugar food additive production, and complete sets of technologies for the green resource utilization of chemical organic hazardous waste, bringing more scientific and technological achievements to people's livelihoods. A "historic breakthrough" has been achieved in the localization of major technical equipment. The company has developed the world's first single 3,000-ton slurry-bed hydrogenation reactor, and possesses the capability to supply complete sets of equipment for 1.5 million t/a ethylene plants (three main units), domestically produced ultra-large low-temperature ethylene cold boxes (high-pressure plate-fin heat exchangers with a design pressure of 12.8 MPa), 450,000 t/a polyethylene, and 400,000 t/a polypropylene extrusion granulators. The styrene plant's four-unit heat exchanger has achieved domestic production, significantly enhancing the industry's self-reliance and controllability in equipment. Significant progress has been made in digital transformation. During the 14th Five-Year Plan period, 44 companies were selected as national intelligent manufacturing pilot demonstration enterprises, and 4 companies were selected as national intelligent manufacturing benchmark enterprises. The self-control rate of major production facilities in petrochemical and coal chemical enterprises exceeded 90%. A number of key enterprises have taken the lead in piloting new-generation information technologies such as cloud computing, big data, artificial intelligence, and the industrial internet, and a total of 59 intelligent manufacturing demonstration plants in the petrochemical and chemical industry have been built, driving the entire industry to accelerate the integration of new technologies.

Green development is accelerating across the board, and a circular and low-carbon system is gradually taking shape.

The circular economy system is becoming increasingly完善. The comprehensive utilization rate of phosphogypsum has increased from 45% to 65%, and the industrial water reuse rate has reached 93%, improving water efficiency. The entire chain of "recycling-sorting-regeneration-high-value utilization" for waste plastics is gradually taking shape, and an efficient circular system of "resource-product-recycled resources" is being rapidly built across the industry. Energy utilization efficiency has been significantly improved. The unit energy intensity of products such as oil refining, ethylene, synthetic ammonia, methanol, urea, phosphate fertilizer, calcium carbide, caustic soda, and soda ash has decreased by 2%-6%, making energy utilization more efficient. Pollution prevention and control have achieved remarkable results. The comprehensive removal rate of volatile organic compounds (VOCs) has increased to over 90%, the industrial wastewater reuse rate exceeds 75%, and the standardized disposal rate of hazardous waste has reached 100%. A complete pollution prevention and control system of "source reduction-process control-end resource utilization" has been basically established. Hundreds of industrial parks and thousands of enterprises have pledged to implement responsible care, further strengthening the industry's green transformation and safe development.

The industrial layout is becoming more rational, and the clustering effect continues to be released.

Significant progress has been made in cluster development. Large-scale integrated refining and chemical projects are further concentrated in coastal petrochemical bases. The refining capacity of the three major regions—the Bohai Rim, Hangzhou Bay, and the Greater Bay Area—accounts for 33% of the national total, and ethylene production capacity accounts for 44.0%. The five major petrochemical industrial clusters are beginning to take shape. Coal chemical bases such as Ordos in Inner Mongolia, Ningdong in Ningxia, and Yulin in Shaanxi have distinctive characteristics, with coal-to-oil, olefins, and ethylene glycol production capacities accounting for 85.9%, 68.3%, and 32.2% of the national total, respectively, further strengthening their regional industrial advantages. The carrying capacity of chemical industrial parks continues to improve. By the end of 2024, 722 chemical industrial parks had been certified nationwide, accounting for over 65% of the industry's output value. The relocation of hazardous chemical enterprises to industrial parks is progressing smoothly. The role of chemical industrial parks in industrial leadership, safety management, and green development is becoming increasingly prominent, making them the "main battleground" for high-quality development in the industry.

With international cooperation working in both directions, the resilience of the industrial chain is constantly being strengthened.

Multinational corporations are increasing their investment in the Chinese market and deepening their localization strategies. ExxonMobil's Huizhou ethylene project has already invested over 31 billion yuan, with an additional 10 billion yuan planned; BASF's Zhanjiang base has a total investment exceeding 10 billion euros; Covestro has invested over 4 billion euros in China, with its Chinese business accounting for over 20% of its global operations; Lanxess, Cabot, Nouryon, Invista, and other companies have made China a key global production base or Asia-Pacific headquarters—Ningbo has become one of Nouryon's global production bases, Invista Shanghai has a globally integrated nylon 66 production base, Cabot's business in China accounts for over 25%, and Clariant plans to increase its local production rate in China to 50%. The supply chain and talent advantages of the Chinese market have become a "growth engine" for the global performance of foreign companies. Chinese petrochemical companies are also actively "going global," expanding their international cooperation opportunities. Sinopec and PetroChina signed cooperation agreements with Qatar Energy for the expansion of the Northern Gas Field, with a total investment of US$28.75 billion. The Liza Phase II project in Guyana, jointly invested by CNOOC, commenced production, marking a breakthrough for Chinese enterprises in oil and gas resource development in the Americas. A consortium formed by CNOOC and PetroChina successfully entered the pre-salt ultra-deepwater oil and gas sector in Brazil. Sinopec actively cooperated with Kazakhstan and Russia on polyethylene and Amur gas chemical complex projects, consolidating its international competitiveness while injecting momentum into the Belt and Road Initiative supply chain cooperation.

Development continues, and we forge ahead again. Standing at the historical juncture of concluding the 14th Five-Year Plan and planning the 15th Five-Year Plan, the petroleum and chemical industry is striving to bring the 14th Five-Year Plan to a successful conclusion and lay a solid foundation for the 15th Five-Year Plan. In the future, the petroleum and chemical industry will continue to pursue higher quality, more efficient, greener, more sustainable, and safer development, contributing even more to achieving the goal of becoming a petrochemical powerhouse and comprehensively advancing China's modernization.

-

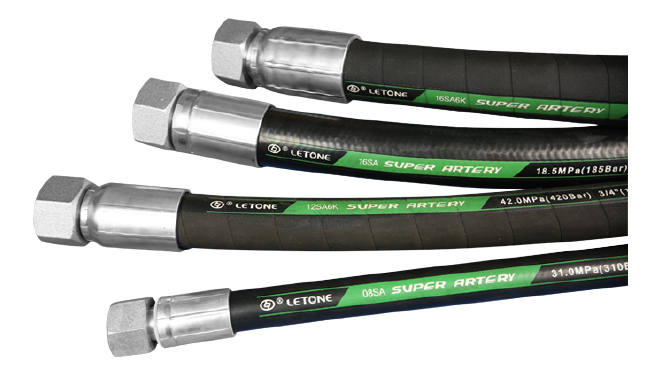

Innovation Empowerment | SUPER ARTERY LOW BEND SERIES Super Hercules Low Bend Series Hose

-

Kerosene cleaning objects and methods

-

Letone Hydraulics sincerely invites you to participate in the "19th Beijing Petroleum and Petrochem

-

Yu Wei, Deputy Mayor of Luohe City, came to investigate

-

Letone Hydraulics sincerely invites you to participate in the 19th China International Petroleum and

-

Letone Hydraulics sincerely invites you to participate in the "Germany Hannover Messe" and "BMW E

-

Letone Hydraulics (Booth No.10152) will meet you at the 2024 Abu Dhabi International Petroleum Expo

-

Up to $1.8 billion! High US tariffs could severely damage the construction machinery industry!