Born for harsh environments | Ultra-wear-resistant mining hydraulic hoses empower smart mines for ef

In the context of the steady development of the global coal industry, safe production in coal mines is a core industry requirement. Coal mining machinery and hydraulic supports, as key equipment to ensure mining safety, are directly related to production efficiency and operational safety through stable operation. The underground environment of coal mines is complex, with dense dust, moisture and easy corrosion, frequent vibration and impact, and narrow working space, which places stringent requirements on hydraulic pipeline systems, requiring them to be ultra-wear-resistant, low-bending, corrosion-resistant, and impact-resistant.

Driven by both tightening coal mine safety policies and the need for automated mining upgrades, Letone Technology, relying on its mature and comprehensive innovative R&D system and stringent full-process quality inspection standards, has accurately identified the core pain points in the operation of hydraulic systems for coal mine machinery. Addressing issues such as rapid hose wear due to dust friction underground, easy corrosion of pipelines in humid environments, leakage under high-pressure vibration conditions, and installation difficulties in confined spaces, Letone has developed a comprehensive mining hydraulic transmission solution covering hoses, self-developed connectors, and seals. From high-intensity coal mine machinery hydraulic supports to high-efficiency integrated coal mining units, from complex and variable underground environments to extreme temperature variations, this solution seamlessly adapts to various coal mine machinery hydraulic transmission needs, comprehensively ensuring the safe, efficient, and stable operation of coal mine production.

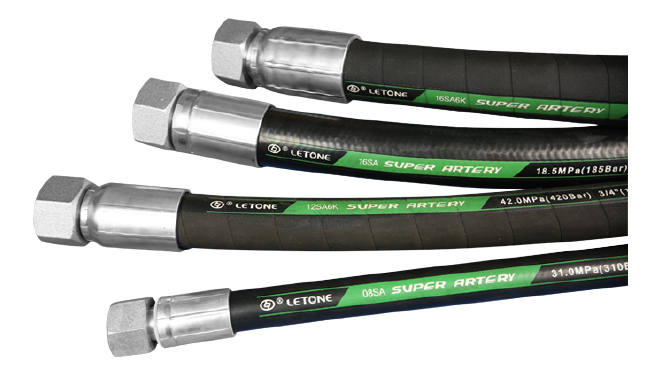

Ultra-wear-resistant mining hydraulic hose

Multi-dimensional core advantages, revitalizing the value of hydraulic transmission

As the core carrier of the solution, ultra-wear-resistant mining hydraulic hoses precisely meet the needs of complex underground environments. With their excellent characteristics of ultra-wear resistance, low bending, high pressure, and corrosion resistance, they reshape the value of hydraulic transmission in coal mines with three core advantages: durability, safety, and ease of installation. Its inner rubber layer is made of oil-resistant synthetic rubber, which is highly resistant to corrosion and media, and can resist the erosion of humid environments and hydraulic media. It is reinforced with a multi-layered high-strength ultra-flexible steel wire layer, which has excellent vibration and impact resistance and can adapt to the continuous impact of equipment operation, ensuring the stability of the pipeline system. The outer layer is covered with a high wear-resistant UPE film and conductive, flame-retardant and ozone-resistant materials, which have extremely strong wear resistance and can resist the friction and extrusion damage of underground dust. It strictly complies with ISO18752 and MT/T98 standards. The outer material mass loss is 0g after 2000 cycles of reciprocating wear test. It is suitable for a wide temperature range of -55℃ to +121℃ and is compatible with a variety of transmission media such as mineral oil, water-based hydraulic oil and water. It fully meets the fluid transportation needs of coal mine hydraulic systems and is perfectly adapted to the working conditions of core equipment such as hydraulic supports and integrated coal mining units.

System-wide collaborative adaptation

Component linkage empowers the creation of integrated solutions

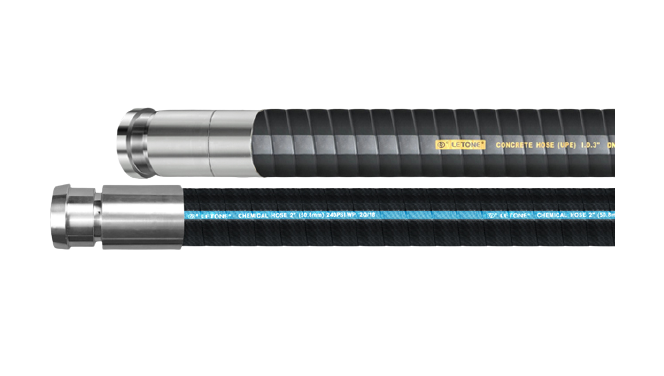

Letone Technology's mining hydraulic transmission solutions not only focus on the performance of core hoses, but also on the new requirements for lightweight, easy-to-install, and multifunctional hydraulic pipeline systems. They integrate a complete hydraulic pipeline system solution (including pipeline design, processing, installation, commissioning, and maintenance services) encompassing hoses, rigid pipes, connectors, and seals, providing a double-layered protective barrier for system sealing and effectively mitigating leakage risks. Simultaneously, they possess excellent oil resistance, wear resistance, and corrosion resistance, resisting erosion from underground moisture and dust, adapting to the harsh working environment of coal mines, and significantly reducing equipment maintenance frequency and costs.

All components undergo rigorous quality testing to ensure that the coal mine hydraulic system maintains excellent performance during long-term, high-intensity operations, with a service life exceeding 5 years and a warranty of up to 3 years. This series of hose assemblies is compatible with hydraulic supports from Beijing Coal Mining Machinery Group and Zhengzhou Coal Mining Machinery Group. Having undergone long-term testing in complex underground environments, the hydraulic hose assemblies demonstrate stable and smooth performance, fully meeting on-site requirements. We strive to provide users with a "five-saving" service: saving time, effort, trouble, money, and worry.

Contextualized and precise adaptation

Covering core operating conditions and ensuring efficient hydraulic transmission

Whether it's the core support hydraulic supports for coal mining machinery or the high-efficiency integrated coal mining units, Letone Technology's ultra-wear-resistant mining hydraulic hose solutions can precisely match the needs of each scenario. In hydraulic support operations, high-pressure transmission places extremely high demands on pipeline stability. Letone Technology's ultra-wear-resistant mining hydraulic hoses' high pressure-bearing capacity and sealing reliability ensure the precise operation of the supports and mitigate safety risks. In integrated coal mining unit operations, complex movements place stringent demands on hose flexibility. The low bending radius characteristics (34% lower than ISO18752 Class C standard) easily adapt to equipment linkage requirements, saving assembly space and time.

From fluid transmission stability to downhole wear resistance, from ease of installation and deployment to long-term operational and maintenance efficiency, Letone Technology's ultra-wear-resistant mining hydraulic hose solutions are backed by over two decades of fluid technology expertise, integrating the concepts of "safety, efficiency, and durability" into every component. In the future, Letone Technology will continue to deepen its expertise in the mining fluid field, leading industry upgrades with new technologies and high-quality products, and injecting safe momentum into the construction of more smart mines with its ultra-wear-resistant mining hydraulic hose solutions, thus building a new pattern of safe, efficient, and intelligent mining.

-

Letone Hydraulics sincerely invites you to participate in the "Germany Hannover Messe" and "Bauma

-

From April 8th to 14th, Letone Hydraulics invites you to participate in the Bauma Exhibition of Muni

-

The Bauma exhibition in Munich is waiting for you at booth C5.114 / D from April 8th to 14th!

-

The first announcement of the environmental impact assessment of the Luohe Letone Hydraulic Technolo

-

We sincerely invite you to participate in the "2019 Fifth China (Changsha) International Constructi

-

Letone Hydraulic "Public Hose Smart Factory Project with an Annual Output of 50 Million Meters" Pu

-

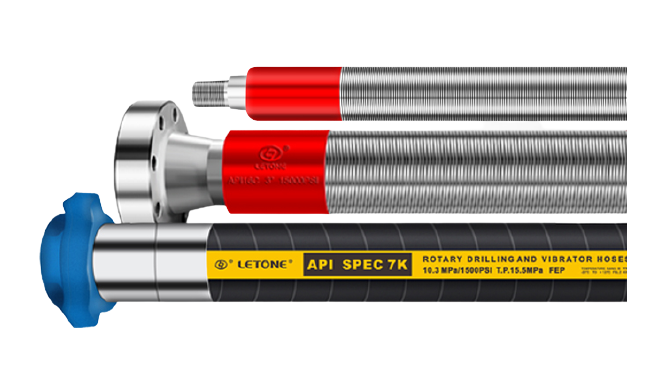

API 7K and API 16C series products successfully obtained ABS certification issued by American Bureau

-

Focusing on ADIPEC 2025 | Letone Technology's scenario-based solutions adapt to a new path for inte