Unlocking the Performance Secrets of Solid-State Batteries: The "High-Voltage Magic" of Thermostat

In the new energy sector, solid-state batteries, with their core advantages of higher safety and longer lifespan, are becoming the core direction of next-generation battery technology. The key to their performance breakthroughs lies in a "hidden black technology"—Warm Isostatic Pressing (WIP). Like a precise "craft master," it solves the interface challenges of solid-state batteries through the synergistic effect of a medium-temperature environment (below 180℃) and ultra-high pressure treatment (approximately 300~600MPa), providing reliable process support for the large-scale production of solid-state batteries.

What is warm isostatic pressing technology?

In simple terms, warm isostatic pressing (WIP) is a high-end molding technology that applies pressure uniformly in all directions. It uses a flexible material as a sheath and a liquid medium (such as water or oil) as the pressure transmission medium. Under a medium temperature environment of 80-180°C, ultra-high pressure of 300-600 MPa is injected into a sealed high-pressure chamber—this pressure is roughly equivalent to the water pressure at a depth of 30,000-60,000 meters, several times that of traditional pressing processes.

Within the high-pressure chamber, the medium pressure is uniformly transmitted in all directions, allowing powdered materials or assembled battery components to eliminate pores and bond tightly under pressure without any dead angles, ultimately forming a product with uniform density and stable performance. This "gentle yet powerful" processing method fully unleashes the potential of materials and has allowed WIP to gain a foothold in many high-end fields.

More than just batteries: "All-round" technology in high-end industrial manufacturing.

The application of warm isostatic pressing (WIP) has long permeated all aspects of high-end industrial fields, especially in areas with stringent material performance requirements:

▶ New material preparation: Forming of preforms for high-temperature alloys, titanium alloys, ceramic matrix composites, and superhard materials (such as silicon nitride and alumina), providing high-performance substrates for aerospace and nuclear energy fields.

▶ Electronics and ceramics: Multilayer ceramic capacitors (MLCC), LTCC/HTCC packaging substrates, high-voltage electromagnetic insulators, etc., ensuring consistent electrical performance and dimensional accuracy;

▶ Special material processing: Enhancing the densification of graphite electrodes, polyamide products, rare earth permanent magnets, and rare metal powders, improving material strength and conductivity;

▶ Precision manufacturing: Automotive engine turbine blades, medical implants (such as ceramic prostheses), cutting tools, etc., meeting the reliability and service life requirements of high-end equipment.

Solid-state batteries' "performance accelerator": The core value of warm isostatic pressing

In the field of solid-state batteries, warm isostatic pressing (WIP) is a key process that is "tailor-made" for specific applications. Currently, the core challenge of solid-state batteries is the interface between the solid electrode and the solid electrolyte—traditional processes easily generate porosity, leading to obstructed ion transport, shortened cycle life, and even safety hazards. WIP perfectly solves this problem.

▶Higher energy density: Eliminating interface porosity improves material utilization, resulting in stronger battery energy storage capacity;

▶Stronger safety: Tight interface bonding prevents electrolyte leakage, reducing the risk of thermal runaway at its source;

▶Longer cycle life: A stable interface structure reduces losses during charging and discharging, extending battery service life;

▶Higher energy efficiency: Optimizes ion transport paths, reduces energy loss, and improves charging and discharging efficiency.

▶Higher energy density: Eliminating interface porosity improves material utilization, resulting in stronger battery energy storage capacity; In short, WIP technology, through its core action of "densification," enables a qualitative leap in the performance of solid-state batteries, providing reliable process support for their transition from laboratory to mass production.

Invitation to explore: The future of solid-state batteries and warm isostatic pressing

Warm isostatic pressing (WIP) technology is injecting powerful momentum into solid-state battery manufacturing, and innovation and breakthroughs in this field cannot be achieved without exchange and collaboration within and outside the industry.

If you are interested in topics such as the technological iteration of solid-state batteries, the application details of WIP equipment, and process optimization directions, please feel free to contact us for discussion. Whether it's technical questions, industry insights, or collaboration ideas, we look forward to exploring more possibilities for the integration of high-end manufacturing and new energy with you!![]()

-

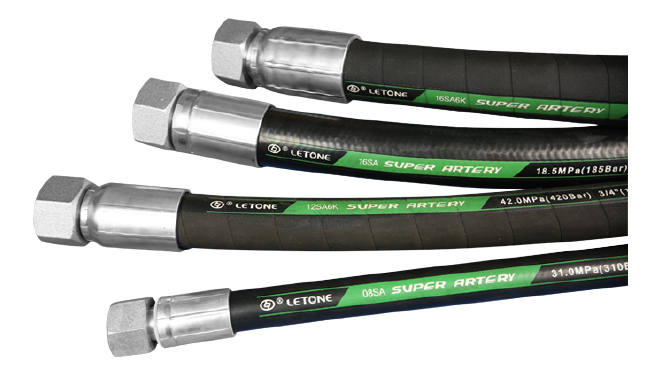

Letone Hydraulics sincerely invites you to participate in the "Germany Hannover Messe" and "Bauma

-

From April 8th to 14th, Letone Hydraulics invites you to participate in the Bauma Exhibition of Muni

-

The Bauma exhibition in Munich is waiting for you at booth C5.114 / D from April 8th to 14th!

-

The first announcement of the environmental impact assessment of the Luohe Letone Hydraulic Technolo

-

We sincerely invite you to participate in the "2019 Fifth China (Changsha) International Constructi

-

Letone Hydraulic "Public Hose Smart Factory Project with an Annual Output of 50 Million Meters" Pu

-

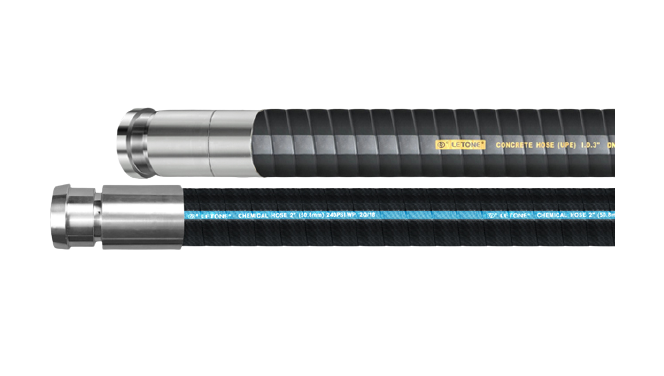

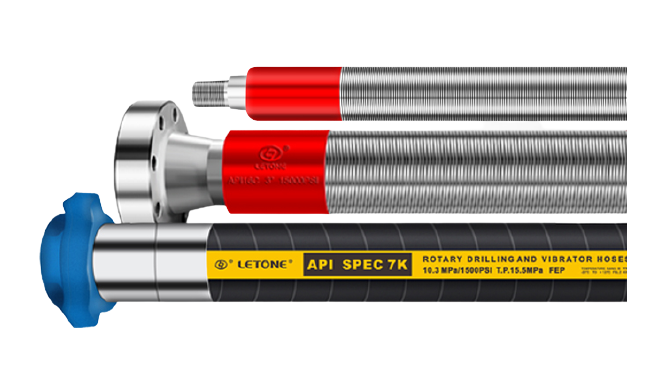

API 7K and API 16C series products successfully obtained ABS certification issued by American Bureau

-

Focusing on ADIPEC 2025 | Letone Technology's scenario-based solutions adapt to a new path for inte