Focusing on the 2025 Trenchless Technology Exhibition | Reckitt Benckiser (Booth No.: H3) – One-stop

On September 4th, the 6th Guangdong-Hong Kong-Macao Greater Bay Area Trenchless Technology Development Forum and Exhibition 2025 grandly opened at the Shenzhen Convention and Exhibition Center (Futian). With "Intelligent Technology and Green Construction" as its core theme, this grand event brought together renowned experts, scholars, and industry elites from home and abroad to deeply explore cutting-edge directions such as digital and intelligent construction and green and low-carbon transformation. Concurrently, a large-scale trenchless exhibition, through a multi-dimensional model of "technical discussions + interactive scenarios + equipment displays + standards guidance," showcased the industry's new technologies, materials, and equipment, and included a popular science experience area for underground pipeline inspection and repair, injecting new momentum into the high-quality development of the trenchless industry.

As a rising force in the field of trenchless pipeline repair, Henan Lijie Environmental Engineering Co., Ltd. (hereinafter referred to as Lijie Environment) was invited to participate in the exhibition. At booth H3, Lijie Environment showcased its newly upgraded core equipment, solutions, and typical cases through brochures, videos, and samples. Its technological innovation and practical applications attracted many visitors who stopped to inquire and engage in in-depth discussions.

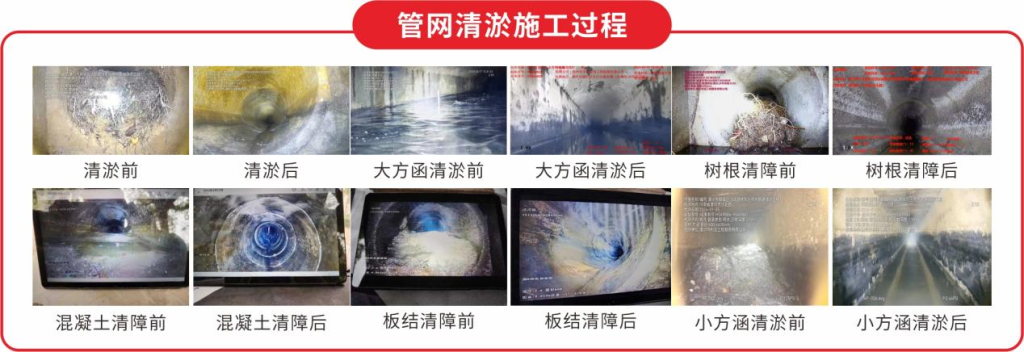

Lijie Environment's exhibited equipment and solutions cover the entire pipeline dredging, cleaning, inspection, and repair chain, highlighting its core advantages of "green, efficient, and intelligent".

1.TTP450 Environmentally Friendly, Low-Noise, High-Efficiency Dredging Equipment

A 450T high-speed, high-flow pump, powered by a diesel engine, operates at a flow rate of 900 L/min and a pressure of 250 bar. It can be connected to a hydraulic slurry pump to solve problems such as urban pipe network dredging and flood control. It can also handle the dredging and deep cleaning of long-distance pipelines with severe blockages and manhole spacing of up to 300 meters.

2.TTP750 Hydraulic Shield Tunneling Equipment

Driven by a diesel engine, this 750T high-speed, high-flow pump operates at 2800 bar and is specifically designed to clear and dredge severely clogged pipes, municipal main pipelines, and stormwater/sewage pipe networks. It can remove hardened deposits and concrete blockages caused by years of neglect in urban pipe networks. It solves the problem of working on long-distance, small-diameter pipes exceeding 100 meters, eliminating the need for manual manhole cleaning and achieving complete clearing and dredging in a single operation.

3. Multi-functional Sewage Suction and Purification Truck

This equipment utilizes a self-developed high-pressure engine unit (outlet pressure 25MPa, flow rate 400L/min), paired with a German high-pressure pump, easily handling complex pipeline dredging tasks such as those involving distances up to 300 meters and large diameters. It supports both diesel engine and mains power drive modes, with energy consumption reduced by 40% in energy-saving mode, and also features an environmentally friendly low-noise design to minimize noise interference. It can quickly deploy a four-stage vortex + screw press nanofiltration system (effluent SS ≤ 10mg/L) in 10 minutes, improving efficiency for on-site wastewater treatment; when connected to a slurry pump, it can also be used for flood control and drainage, achieving multi-functionality.

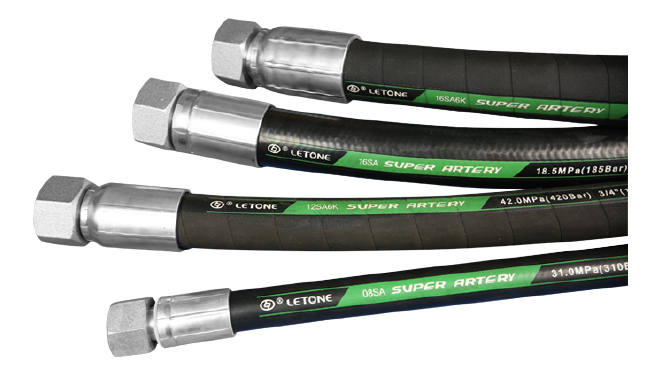

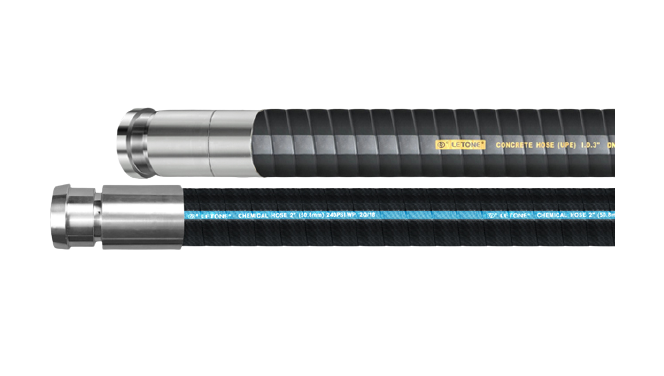

4.Ultra-high pressure resin hoses

This series of hoses features low bending, high pressure, ultra-wear resistance, wide compatibility, and resistance to high and low temperatures. With a working pressure of 400MPa and a burst pressure of 1000MPa, it can meet the stringent reliability, stability, and safety requirements of various scenarios, including waterway cleaning, pipeline cleaning, shell-and-tube heat exchanger cleaning, water jet cutting, concrete cutting, and high-pressure cleaning in the petrochemical, natural gas, shipbuilding, and automotive industries.

5. High-Efficiency Solutions for Municipal Pipeline Networks

We have built a comprehensive service system encompassing "detection—blockage removal—dredging—repair," providing clients with professional services and customized solutions that exceed their expectations.

Lijie Environment integrates green innovation concepts into its technological research and development. Leveraging ultra-high pressure water jet technology, we efficiently address industry pain points such as the treatment of black and odorous water bodies and the dredging of severe blockages in municipal pipe networks using trenchless methods. In a municipal pipe network blockage removal and dredging project in Shunde District, Foshan City, facing the formidable challenge of two sections of corrugated pipes—a 30-meter blockage caused by solidified concrete and a 70-meter blockage caused by completely silt—and the complex situation of nearby communication cables making excavation impossible, the Lijie team used a combination of ultra-high pressure water jet tunneling equipment and intelligent detection equipment to completely dredge the pipes in just 2 hours. This operation completely replaced manual well-drilling and excavation, increasing efficiency by more than three times and winning high praise from local water authorities and residents.

Currently, Lijie Environment's one-stop municipal pipeline network solutions have covered multiple cities such as Zhongshan, Foshan, and Luohe. With its professional technology and high-quality service, it has won widespread praise from owners and is dedicated to protecting the underground "lifeline" of every city.

The Trenchless Technology Exhibition is currently underway, and Reckitt Benckiser cordially invites new and existing customers and industry colleagues to visit booth H3 to experience firsthand the cutting-edge applications of ultra-high pressure hydraulic shield tunneling technology and jointly discuss hot and key issues in underground pipeline networks and the trenchless industry. In the future, Reckitt Benckiser will continue to deepen its technological innovation, working hand in hand with industry partners to thoroughly implement the strategic deployment of the "14th Five-Year Plan," contributing to the high-quality development of the Guangdong-Hong Kong-Macao Greater Bay Area and jointly building a better future for smart cities.

-

Letone Hydraulics sincerely invites you to participate in the "Germany Hannover Messe" and "Bauma

-

From April 8th to 14th, Letone Hydraulics invites you to participate in the Bauma Exhibition of Muni

-

The Bauma exhibition in Munich is waiting for you at booth C5.114 / D from April 8th to 14th!

-

The first announcement of the environmental impact assessment of the Luohe Letone Hydraulic Technolo

-

We sincerely invite you to participate in the "2019 Fifth China (Changsha) International Constructi

-

Letone Hydraulic "Public Hose Smart Factory Project with an Annual Output of 50 Million Meters" Pu

-

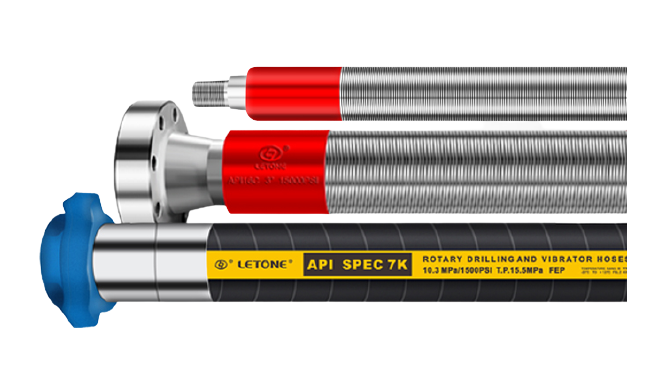

API 7K and API 16C series products successfully obtained ABS certification issued by American Bureau

-

Focusing on ADIPEC 2025 | Letone Technology's scenario-based solutions adapt to a new path for inte