Focusing on China Coal & Mining Expo 2025 | Letone Technology Breaks Through with New Productivity,

On October 28th, the 21st China International Coal & Mining Technology Exchange and Equipment Exhibition (China Coal & Mining Expo 2025) was grandly held at the China International Exhibition Center (Shunyi Hall) in Beijing. With "Intelligent Upgrading, Safety Improvement, and Green Transformation" as its core themes and "New Quality Empowerment, Intelligent Future," this year's exhibition showcased the latest equipment, technologies, and products in the coal mining industry.

As a leading enterprise in China's hose industry, Letone Technology (booth number: B5359) has participated in the China International Coal Mining Technology Exchange and Equipment Exhibition for many consecutive years. Focusing on "technological innovation" and "scenario implementation" to drive new quality productivity, Letone Technology has become one of the most popular companies at the exhibition, thanks to its strong product capabilities and safe, efficient solutions.

This year, Letone Technology fully aligned with the exhibition's "New Quality Empowerment" concept, showcasing its flagship products, including customized ultra-wear-resistant mining hoses with outer coatings, the upgraded Super Hercules low-bend series hoses, ultra-high pressure resin hoses, and a full range of fluid connectors. Through "material innovation + process upgrades," Letone Technology comprehensively demonstrated its new achievements and breakthroughs in supporting the low-carbon, intelligent, and green development of the coal industry, winning high recognition from both new and existing customers and industry experts.

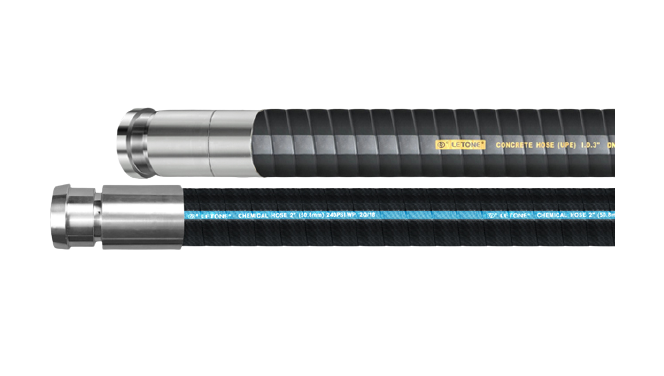

Customized outer coating for ultra-wear resistant mining hose

This series of hoses uses a polymer material outer coating. According to GB/T12721-2007 standard, after 2000 cycles of reciprocating abrasion test, the mass loss of the outer material of the customized ultra-wear-resistant mining hose with outer coating by Letone Technology is 0g.

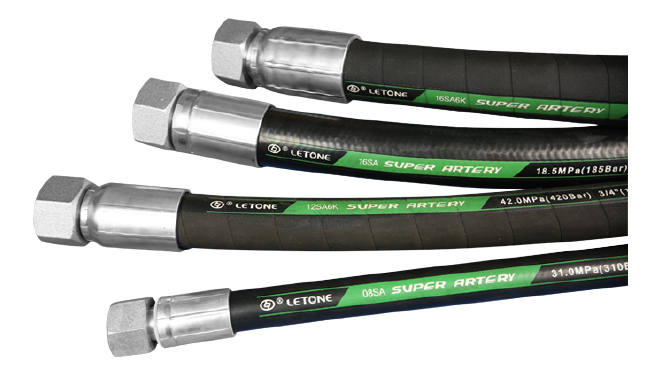

Super Hercules Low Bending Series Hose

Low Bending Radius: Bending radius reduced by 30% compared to SAE/DIN standards, weight reduced by 30%, leaving more space for core components.

High Pressure: Working pressure increased by 25% compared to SAE/DIN standards, with a 4-fold safety factor, preventing bursting under high pressure.

Long Lifespan: Powerful pulse performance, the hose can withstand up to 1 million pulse cycles, significantly extending its service life.

This series of hoses uses Letone's self-developed hose fittings and hydrogenated nitrile butadiene seals, offering over 5 years of weather resistance and a 3-year warranty.

Ultra-high pressure resin hose

Ultra-high pressure resistance: Working pressure up to 400MPa;

Doubled flexibility: Bending radius reduced by 15% compared to the industry average;

Safety assurance: 2.5 times safety factor, burst pressure 1000MPa.

Suitable for conveying media such as water and hydraulic oil under high pressure, widely used in high-pressure spraying, high-pressure cleaning, ship cleaning, sandblasting, construction machinery, agricultural and forestry machinery, petrochemical and other industries.

Fluid Connectors

Product Types: Engineering machinery hose fittings, mining hose fittings, transition fittings, quick couplings, pressure testing fittings, high-pressure rigid pipes, non-standard customized fittings, etc.

Product Applications: Widely used in engineering machinery, agricultural machinery, coal mining machinery, railway locomotives, automobile manufacturing, shipbuilding, and other industries.

Safeguarding coal mining safety, Letone Technology adheres to the R&D and production philosophy of "safety first, quality foremost," integrating the core requirements of new quality productivity into the entire product lifecycle—from polymer material R&D to intelligent production process optimization, and precise adaptation to mining scenarios. Through differentiated innovation, Letone Technology accelerates the transformation of old and new growth drivers in the industry, continuously improving its R&D, design, and manufacturing capabilities for integrated mining pipeline solutions, creating safe and efficient mining hydraulic hoses and assemblies.

Against the backdrop of "dual carbon" goals and energy structure adjustments, Letone Technology (booth number: B5359) will continue to be guided by new quality productivity, focusing on technological breakthroughs in the intelligent transformation and upgrading of coal mine hydraulic support manufacturing. This will further improve the safety, stability, and reliability of its products, meeting the requirements of hydraulic systems in integrated coal mining units for pressureless delivery of coal mine oil, water-based hydraulic oil, or water under extremely high-pressure and harsh conditions. This will accelerate the industry's progress towards "low-carbon, intelligent, efficient, and safe" manufacturing.

Letone Technology sincerely invites new and existing customers to visit booth B5359 for exchange and cooperation. Together, we will use new quality productivity as an engine to inject strong momentum into the transformation of the coal mining industry from "manufacturing" to "intelligent manufacturing," composing a new chapter in the high-quality development of the coal mining energy industry.

-

Letone Hydraulics sincerely invites you to participate in the "Germany Hannover Messe" and "Bauma

-

From April 8th to 14th, Letone Hydraulics invites you to participate in the Bauma Exhibition of Muni

-

The Bauma exhibition in Munich is waiting for you at booth C5.114 / D from April 8th to 14th!

-

The first announcement of the environmental impact assessment of the Luohe Letone Hydraulic Technolo

-

We sincerely invite you to participate in the "2019 Fifth China (Changsha) International Constructi

-

Letone Hydraulic "Public Hose Smart Factory Project with an Annual Output of 50 Million Meters" Pu

-

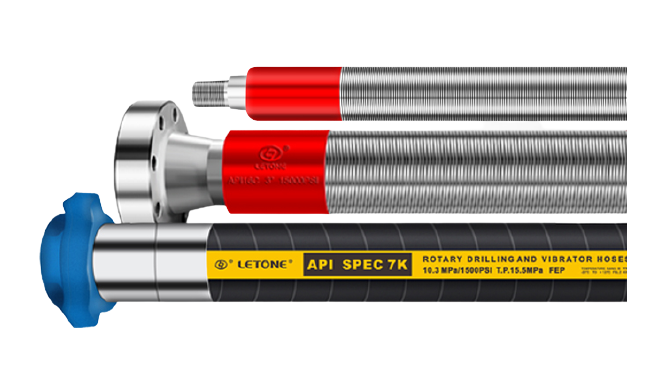

API 7K and API 16C series products successfully obtained ABS certification issued by American Bureau

-

Focusing on ADIPEC 2025 | Letone Technology's scenario-based solutions adapt to a new path for inte