Quintus Technologies unveils next-generation warm isostatic press to accelerate mass production of a

In November 2025, a major breakthrough will be achieved in the global high-voltage technology field: Swedish company Quintus Technologies will officially launch the QIB 300 and QIB 600 series of warm isostatic presses specifically designed for pilot production of all-solid-state batteries. This technological innovation not only marks a crucial step in the commercialization of all-solid-state batteries, but also injects strong momentum into the new energy industry by solving the core pain points of traditional processes.

Technological Breakthrough: Solving the Material Interface Problem

The core advantage of all-solid-state batteries lies in their solid electrolyte replacing the traditional liquid electrolyte. However, poor material interface contact leading to increased resistance and performance degradation has consistently hindered their development. Traditional uniaxial pressing processes, due to uneven pressure distribution, struggle to achieve uniform bonding between the electrodes and electrolyte. The QIB series equipment, however, employs isostatic pressing technology, applying uniform pressure to the material at 145°C using a high-pressure medium (such as argon), with peak pressure reaching 600 MPa. This "three-dimensional encapsulation" pressing reduces material porosity to below 0.1%, improves interface contact tightness by 40%, and significantly reduces battery internal resistance, laying the foundation for manufacturing high-energy-density, long-cycle-life batteries.

Design Innovation: A Seamless Journey from Lab to Mass Production

The horizontal loading system and modular design of the QIB series equipment are another major highlight. Traditional equipment suffers from a high risk of cell deformation due to vertical loading, while the horizontal structure, combined with customized fixtures, improves cell loading efficiency by 30% while reducing manual intervention. The equipment supports a smooth upgrade from laboratory-level (300 MPa) to industrial-level (600 MPa), and through precise control of pressure, temperature, and time, it can quickly verify the performance of different material combinations. For example, when testing sulfide electrolytes, the equipment can simulate the mechanical conditions under mass production conditions, accelerating the process optimization cycle. This integrated design of "R&D-pilot production-mass production" shortens the industrialization time of all-solid-state batteries to 18-24 months.

Industry Impact: Driving the New Energy Revolution

All-solid-state batteries are considered the "holy grail" of next-generation battery technology, boasting an energy density 2-3 times that of traditional lithium-ion batteries while completely eliminating the risk of thermal runaway. The launch of the QIB series of devices directly addresses the core technological bottleneck from laboratory to mass production. Currently, this technology has attracted the attention of numerous international battery companies, including leading companies such as Toyota and QuantumScape. It is predicted that the global all-solid-state battery market will exceed $5 billion by 2026, with Quintus' devices expected to capture more than 30% of the market share. Furthermore, this technology can be extended to hydrogen fuel cells, solid oxide electrolyzers, and other fields, driving a comprehensive upgrade of the new energy industry.

Challenges and Prospects

Despite the immense potential of the QIB series equipment, its high cost (over $2 million per unit) and complex processes remain challenges for large-scale production. In the future, Quintus needs to further reduce costs through material innovation (such as low-cost ceramic dielectrics) and intelligent control (AI algorithms optimizing pressing parameters). Simultaneously, the industry needs to establish unified process standards to avoid performance fluctuations caused by equipment differences. With continuous optimization, all-solid-state batteries are expected to achieve mass production by 2027, fundamentally changing the landscape of new energy vehicles, energy storage, and other fields.

Conclusion

Quintus Technologies' warm isostatic press technology represents not only a breakthrough in equipment but also a crucial bridge between "laboratory exploration" and "commercial application" in the new energy industry. By solving the core challenge of material interfaces, it accelerates the industrialization of all-solid-state batteries, providing a novel solution for global energy transition. With technological iteration and cost reduction, all-solid-state batteries may become the most disruptive energy technology of the next decade.

-

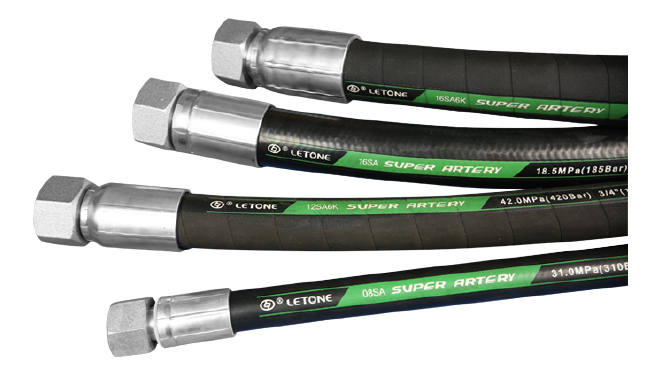

Innovation Empowerment | SUPER ARTERY LOW BEND SERIES Super Hercules Low Bend Series Hose

-

Kerosene cleaning objects and methods

-

Letone Hydraulics sincerely invites you to participate in the "19th Beijing Petroleum and Petrochem

-

Yu Wei, Deputy Mayor of Luohe City, came to investigate

-

Letone Hydraulics sincerely invites you to participate in the 19th China International Petroleum and

-

Letone Hydraulics sincerely invites you to participate in the "Germany Hannover Messe" and "BMW E

-

Letone Hydraulics (Booth No.10152) will meet you at the 2024 Abu Dhabi International Petroleum Expo

-

Up to $1.8 billion! High US tariffs could severely damage the construction machinery industry!