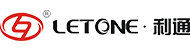

Rubber Compound

Rubber compound is an important raw material for hose products and sealing products, and is the cornerstone of product quality for rubber product manufacturers. According to the user's differential performance requirements for the rubber compound, LETONE provides professionally customized NR (Natural Rubber), SBR (Styrene Butadiene Rubber), EPDM (EPDM Rubber), NBR (Nitrile Butadiene Rubber), HNBR (Hydrogenated Rubber) Nitrile rubber), CR (neoprene rubber) and other high-performance compound rubber products and related technical services.

-

lth01

lth01CR-Neoprene

Introduction:Chloroprene Rubber CR (Chloroprene Rubber) has high tensile strength, elongation and other physical mechanical properties, and has good oil resistance, heat aging resistance, flame retardant, light resistance, ozone resistance, acid and alkali resistance , Chemical resistance and other chemical properties. Therefore, it is widely used in the manufacture of hoses, tapes, wire and cable sheaths, rubber rollers, rubber plates, adhesives and various sealed shock-absorbing products

Tips:Neoprene rubber compound, full-color hardness range customized, hardness 20-95 degrees. The formula can be prepared according to the specific requirements of customer products -

lth02

lth02NR-natural rubber compound

Introduction:Natural Rubber (Natural Rubber) has excellent resilience, abrasion resistance, tear resistance, high tensile strength and other physical and mechanical properties, as well as good electrical insulation, water barrier, air tightness, resistance Electrochemical properties such as acidity and alkalinity. Therefore, natural rubber is often used in rubber tires, hoses, tapes, and various shock-absorbing and sealing products

Tip:According to customer needs, Litong can customize natural rubber compound with full color and hardness range of 20-95 degrees -

lth03

lth03HNBR-Hydrogenated Nitrile Rubb

Application:Widely used in the automotive and oil field industries, used to manufacture hoses, rubber plates and sealed shock-absorbing products, especially oil-resistant rubber products that require high temperature resistance, aging resistance and corrosion resistance

Introduction:Hydrogenated Nitrile Rubber HNBR (Hydrogenated Nitrile Rubber) is a highly saturated elastomer obtained by special hydrogenation of nitrile rubber. Hydrogenated nitrile rubber has good oil resistance (good resistance to fuel oil, lubricating oil, aromatic solvents); and due to its highly saturated structure, it has good heat resistance and excellent chemical resistance (for Freon, acid and alkali have good resistance), excellent ozone resistance, high resistance to compression permanent deformation; at the same time hydrogenated nitrile rubber also has high strength, high tear performance, excellent wear resistance, etc. It is a rubber with excellent overall performance -

lth04

lth04SBR-Styrene Butadiene Rubber

Introduction:Polymerized Styrene Butadiene Rubber (Polymerized Styrene Butadiene Rubber) has physical and mechanical properties, processing properties and product performance close to that of natural rubber. Some properties such as wear resistance, heat resistance, aging resistance and vulcanization return are better than natural rubber , Can be used in combination with natural rubber and various synthetic rubbers, widely used in the production of tires, tapes, hoses, wires and cables, medical appliances and various rubber products. One of the rubber varieties produced

Tip:According to customer needs, Litong can customize styrene-butadiene rubber compound with full color and hardness range of 20-95 degrees -

lth05

lth05EPDM- EPDM compound

Introduction:Ethylene Propylene Diene Monomer has excellent ozone resistance, weather resistance, heat aging resistance, good chemical corrosion resistance, electrical insulation performance, hot water and steam resistance, and low temperature resistance. Therefore, EPDM is mainly used in automotive parts (scrapers, seals, dustproof rubber sleeves and other sealed shock-absorbing products), chemical-resistant hoses, rubber rollers, gaskets, etc., as well as high, medium and low voltage insulation Rubber material

Tip:According to customer needs, Litong can customize EPDM rubber compound with full color and hardness range of 20-95 degrees -

lth06

lth06NBR-nitrile rubber compound

Introduction:NBR (Nitrile Butadiene Rubber) has excellent oil resistance, air tightness, good water resistance, acid and alkali resistance, good wear resistance and aging resistance. The performance of nitrile rubber varies slightly according to the distribution of its molecular segments. Therefore, nitrile rubber is widely used in oil-resistant rubber products, such as hoses, rubber rollers, seals and shock-absorbing products

Tip:According to customer needs, Litong can customize full-color nitrile rubber compound with a hardness range of 20-95 degrees

- Product Navigation