Rubber Compound and Rubber-plastic Sealing Product

Letone has independently developed, designed and manufactured rubber compounds for more than 10 years. It has an experienced technical team, complete production and experimental equipment and a good reputation in the industry. Letone is now cooperating with the German-owned Shifa (Shanghai) Hydraulic Technology Co., Ltd. to manufacture and sell rubber compounds and sealing products. The products have both Chinese and Western technical advantages, stable quality and excellent performance.

-

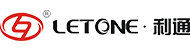

Rubber Compound

Rubber compound is an important raw material for hose products and sealing products, and is the cornerstone of product quality for rubber product manufacturers. According to the user's differential performance requirements for the rubber compound, LETONE provides professionally customized NR (Natural Rubber), SBR (Styrene Butadiene Rubber), EPDM (EPDM Rubber), NBR (Nitrile Butadiene Rubber), HNBR (Hydrogenated Rubber) Nitrile rubber), CR (neoprene rubber) and other high-performance compound rubber products and related technical services.

-

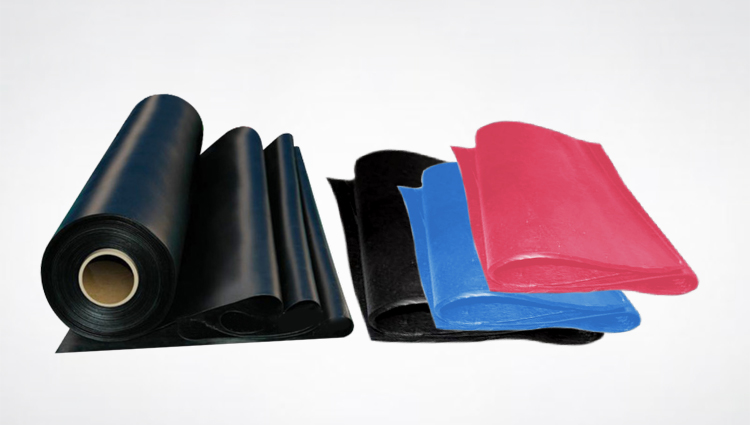

Food Grade Rubber Compound

LETONE food-grade compound rubber complies with FDA testing standards, and is non-toxic, colorless and odorless. According to user needs, the product can be customized for use temperature, wear resistance, adhesion and other properties.

-

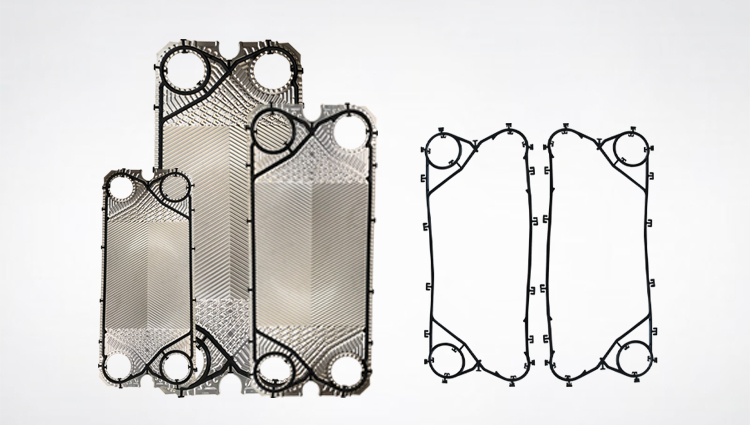

Gasket for Plate Heat Exchanger

The plate heat exchanger gaskets jointly designed and manufactured by LETONE and the German-owned enterprise SEAFAR (Shanghai) Hydraulic Technology Co., Ltd. have various types, good sealing performance and long service life. They can be used with Alfa Laval, Tranter , Thermowave and other brands of plate heat exchangers for supporting use.

-

Rubber Soft Connection

Rubber joints are widely used in metallurgy, petrochemical, electric power, energy, transportation, chemical industry, construction, cement, urban heating and other fields. According to the needs of the medium used and the environment, LETONE rubber compensators can be customized with various properties such as acid resistance, alkali resistance, oil resistance, heat resistance, and corrosion resistance. They have the characteristics of good sealing, light weight, and long life.

-

Plate Heat Exchanger

Plate heat exchangers have the advantages of high heat exchange efficiency, small footprint, simple manufacturing and maintenance, and are suitable for district heating, domestic hot water, ice storage, swimming pool constant temperature, etc. in the HVAC field